Table of Content

- What is Incoloy 800/800H/800HT Washers

- Incoloy 800/800H/800HT Washers Specification

- Incoloy 800/800H/800HT Washers Equivalent Grade

- Types of Incoloy 800/800H/800HT Washers

- Incoloy 800/800H/800HT Washers Price List

- Size Chart Of Incoloy 800/800H/800HT Washers

- Dimensions of Alloy 800/800H/800HT Spring Washer

- Weight Chart Of Incoloy Alloy 800/800H/800HT Washers

- Chemical Composition of Grade 800/800H/800HT Incoloy Washers

- Mechanical Properties of Incoloy 800/800H/800HT Washers

- Other Types of Incoloy 800/800H/800HT Washers

- Incoloy 800/800H/800HT Washers Application Area

- Other Stock of Incoloy Washers

Incoloy 800 Washer, Best Deals on Incoloy UNS N08800 Washers, Incoloy 800HT Industrial Washers, ASTM B408 Allo 800 Plain Washers, Werkstoff Nr.1.4876 Spring Washer, 800HT Incoloy Locking Washer, Incoloy Alloy 800H Flat Washer, Alloy 800H Fender Washer, Incoloy 800 Star Washer Supplier in India.

Kalpatru is a recognized supplier of Incoloy Alloy 800 / 800H / 800HT Washers, which is especially suitable for sheet applications. Incoloy 800 Flat Washers provide very good corrosion and oxidation resistance at high temperatures. The versatility of this Incoloy 800H Lock Washers allows it to be machined into a wide range of forms making it ideal for use across different industries. Incoloy 800HT Sealing Washers has ability to withstand very high temperatures, and is ideal for its use in aircraft parts and in gas tribune components, such as exhaust nozzles on jet engines and turbine blades. Incoloy UNS N08800 Split Washers is a precipitation-hardenable nickel-chromium-cobalt alloy by means of having an addition of molybdenum for solid-solution strengthening. Incoloy UNS N08810 Slot Washers has high strength and corrosion resistance along in the company of good formability and high-temperature ductility in welded structures. These Incoloy UNS N08811 Machine Washers are used in gas turbines for rings, casings, and various sheet fabrications. Incoloy DIN 1.4876 Star Washers is a precipitation-hardenable nickel-chromium-cobalt alloy having high stress-rupture strength and creep resistance at temperatures to about 1700°F (920°C). Incoloy DIN 1.4958 Spring Washers also has good resistance to high-temperature corrosion and oxidation. Incoloy DIN 1.4859 Wire Spring Washers are often used for tube supports in nuclear generators, exhaust valves in internal combustion engines. Nickel Alloy 800 Flat Spring Washers have many other offshore / marine, automotive and electrical applications.

High Quality Incoloy 800 Ogee Washers, Incoloy Alloy 800HT Square Washer, Large Selection of Incoloy 800H Washers, ASME SB408 Incoloy 800 Countersunk Washer, Incoloy DIN 1.4958 Star Washers, Incoloy UNS N08810 Machine Washer, Alloy 800 Spring Washer Dealer, Incoloy N08811 Tooth Lock Washer, Incoloy 800HT Split Ring Washer, Incoloy N08811 Washers Exporter.

Incoloy 800/800H/800HT Washers Specification

Incoloy 800/800H/800HT Washers Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN | OR |

| Incoloy 800 | 1.4876 | N08800 | NCF 800 | NA 15 | ЭИ670 | Z8NC32-21 | X10NiCrAlTi32-20 | XH32 |

| Incoloy 800H | 1.4958 / 1.4876 | N08810 | NCF 800H | NA 15(H) | ЭИ670 | Z8NC33-21 | X5NiCrAlTi31-20 | XH32T |

| Incoloy 800HT | 1.4859 / 1.4876 | N08811 | NCF 800HT | NA 15(HT) | ЭИ670 | - | X8NiCrAlTi32-21 | XH32T |

Types of Incoloy 800/800H/800HT Washers

Incoloy 800/800H/800HT Dock Washer

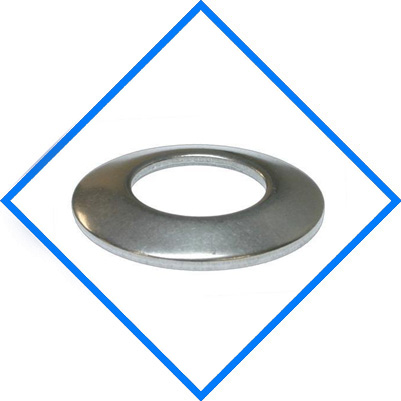

Incoloy 800/800H/800HT Belleville Washer

Incoloy 800/800H/800HT Fender Washer

Incoloy 800/800H/800HT Countersunk Finishing Washer

Incoloy 800/800H/800HT Ogee Washer

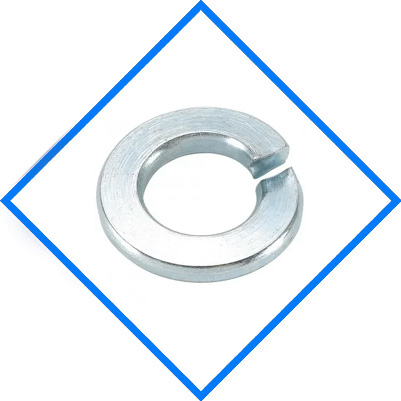

Incoloy 800/800H/800HT Split Washer

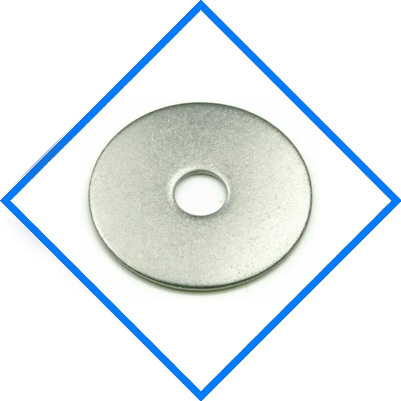

Incoloy 800/800H/800HT Flat Washer

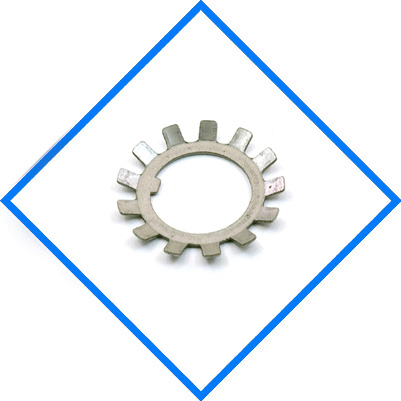

Incoloy 800/800H/800HT Star Washer

Incoloy 800/800H/800HT Square Washers

Incoloy 800/800H/800HT Spring Washer

Incoloy 800/800H/800HT Lock Washer

Incoloy 800/800H/800HT Spherical Washer

Incoloy 800/800H/800HT Washers Price List

We offer wide range of industrial Incoloy 800/800H/800HT Washers that in compliance with IS, BS and DIN standards at best market prices in India. To know more about the latest price of Incoloy 800/800H/800HT Washers Please Call +91 22-66337137 or Send an Email to info@flangesbolts.com

Size Chart Of Incoloy Washers

| Size | USS | SAE | ||||

|---|---|---|---|---|---|---|

| Inside Diameter (A) |

Outside Diameter (B) |

Thickness (C) |

Inside Diameter (A) |

Outside Diameter (B) |

Thickness (C) |

|

| #2 | – | – | – | 3/32″ | 1/4″ | 0.020″ |

| #4 | – | – | – | 1/8″ | 5/16″ | 0.032″ |

| #6 | – | – | – | 5/32″ | 3/8″ | 0.049″ |

| #8 | – | – | – | 3/16″ | 7/16″ | 0.049″ |

| #10 | – | – | – | 7/32″ | 1/2″ | 0.049″ |

| #12 | – | – | – | 1/4″ | 9/16″ | 0.065″ |

| 1/4″ | 5/16″ | 0.734″ | 0.065″ | 9/32″ | 5/8″ | 0.065″ |

| 5/16″ | 3/8″ | 7/8″ | 0.083″ | 11/32″ | 11/16″ | 0.065″ |

| 3/8″ | 7/16″ | 1″ | 0.083″ | 13/32″ | 13/16″ | 0.065″ |

| 7/16″ | 1/2″ | 1-1/4″ | 0.083″ | 15/32″ | 15/16″ | 0.065″ |

| 1/2″ | 9/16″ | 1-3/8″ | 0.109″ | 17/32″ | 1-1/16″ | 0.095″ |

| 9/16″ | 5/8″ | 1-15/32″ | 0.109″ | 19/32″ | 1-5/32″ | 0.095″ |

| 5/8″ | 11/16″ | 1-3/4″ | 0.134″ | 21/32″ | 1-5/16″ | 0.095″ |

| 3/4″ | 13/16″ | 2″ | 0.148″ | 13/16″ | 1-15/32″ | 0.134″ |

| 7/8″ | 15/16″ | 2-1/4″ | 0.165″ | 15/16″ | 1-3/4″ | 0.134″ |

| 1″ | 1-1/16″ | 2-1/2″ | 0.165″ | 1-1/16″ | 2″ | 0.134″ |

| 1-1/8″ | 1-1/4″ | 2-3/4″ | 0.165″ | – | – | – |

| 1-1/4″ | 1-3/8″ | 3″ | 0.165″ | – | – | – |

| 1-3/8″ | 1-1/2″ | 3-1/4″ | 0.180″ | – | – | – |

| 1-1/2″ | 1-5/8″ | 3-1/2″ | 0.180″ | – | – | – |

| 1-5/8″ | 1-3/4″ | 3-3/4″ | 0.180″ | – | – | – |

| 1-3/4″ | 1-7/8″ | 4″ | 0.180″ | – | – | – |

| 2″ | 2-1/8″ | 4-1/2″ | 0.213″ | – | – | – |

Dimensions of Alloy 800/800H/800HT Flat Washer

| Bolt Size | USS | SAE | ||||

| OD (in.) | ID (in.) | Thickness | OD (in.) | ID (in.) | Thickness | |

| 1/8 (#6) | – | – | – | 0.375 | 0.156 | .036/.065 |

| 5/32 (#8) | – | – | – | 0.438 | 0.188 | .036/.065 |

| 3/16 (#10) | 0.560 | 0.250 | .036/.065 | 0.500 | 0.220 | .036/.065 |

| 7/32 (#12) | – | – | – | 0.562 | 0.250 | .051/.080 |

| 1/4 (#14) | 0.734 | 0.312 | .051/.080 | 0.625 | 0.281 | .051/.080 |

| 5/16 | 0.875 | 0.375 | .064/.104 | 0.688 | 0.344 | .051/.080 |

| 3/8 | 1.000 | 0.438 | .064/.104 | 0.812 | 0.406 | .051/.080 |

| 7/16 | 1.250 | 0.500 | .064/.104 | 0.922 | 0.469 | .051/.080 |

| 1/2 | 1.375 | 0.562 | .086/.132 | 1.062 | 0.531 | .074/.121 |

| 9/16 | 1.469 | 0.625 | .086/.132 | 1.156 | 0.594 | .074/.121 |

| 5/8 | 1.750 | 0.688 | .108/.160 | 1.312 | 0.656 | .074/.121 |

| 3/4 | 2.000 | 0.812 | .122/.177 | 1.469 | 0.812 | .108/.160 |

| 7/8 | 2.250 | 0.938 | .136/.192 | 1.750 | 0.938 | .108/.160 |

| 1 | 2.500 | 1.062 | .136/.192 | 2.000 | 1.062 | .108/.160 |

| 1 1/8 | 2.750 | 1.250 | .136/.192 | 2.250 | 1.250 | .108/.160 |

| 1 1/4 | 3.000 | 1.375 | .136/.192 | 2.500 | 1.375 | .136/.192 |

| 1 3/8 | 3.250 | 1.500 | .153/.213 | 2.750 | 1.500 | .136/.213 |

| 1 1/2 | 3.500 | 1.625 | .153/.213 | 3.000 | 1.625 | .153/.213 |

| 1 5/8 | 3.750 | 1.750 | .153/.213 | – | – | – |

| 1 3/4 | 4.000 | 1.875 | .153/.213 | – | – | – |

| 1 7/8 | 4.250 | 2.000 | .153/.213 | – | – | – |

| 2 | 4.500 | 2.125 | .153/.213 | – | – | – |

| 2 1/4 | 4.750 | 2.375 | .320/.248 | – | – | – |

| 2 1/2 | 5.000 | 2.625 | .210/.280 | – | – | – |

| 2 3/4 | 5.250 | 2.875 | .228/.410S | – | – | – |

| 3 | 5.500 | 3.125 | .249/.327 | – | – | – |

Weight Chart Of Incoloy Alloy 800/800H/800HT Washers

| APPROX. WEIGHT IN KGS FOR 100 NOS | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SIZE | PLAIN PUNCHED WASHER IS:2016 |

HEAVY WASHER IS:6610 |

MACHINED WASHER IS:2016 |

SQUARE | TAPER | WASHERS | SPRING WASHER FLAT SECTION IS:3063-72 | SPRING WASHER SQUARE SECTION IS:6735-72 DIN : 7980 |

Size (Inches) | PLAIN PUNCHED WASHER BS:3410 TABLE 7 |

|||

| MACHINED | HIGH STRENGTH FRICTION GRIP |

||||||||||

| FOR CHANNELS IS:5372-75 |

FOR I-BEAM IS:5374-75 |

TYPE-B (CHANNELS) IS : 6649-85 |

TYPE-C ( I-BEAMS ) IS : 6649-85 |

||||||||

| M-3 | 0.01 | 0.01 | |||||||||

| M-4 | 0.02 | 0.02 | |||||||||

| M-5 | 0.04 | 0.04 | 0.03 | 0.03 | |||||||

| M-6 | 0.11 | 0.11 | 0.08 | 0.04 | 1/4″ | 0.21 | |||||

| M-8 | 0.20 | 0.21 | 1.10 | 1.20 | 0.16 | 0.11 | 5/16″ | 0.35 | |||

| M-10 | 0.39 | 1.60 | 0.40 | 1.00 | 1.10 | 0.25 | 0.20 | 3/8″ | 0.48 | ||

| M-12 | 0.58 | 1.90 | 0.62 | 2.00 | 2.20 | 2.00 | 1.80 | 0.38 | 0.23 | 1/2″ | 1.07 |

| M-14 | 0.82 | 0.60 | 0.38 | ||||||||

| M-16 | 1.06 | 2.90 | 1.13 | 3.40 | 3.75 | 9.00 | 8.50 | 0.89 | 0.59 | 5/8″ | 1.85 |

| M-18 | 1.27 | 0.97 | 0.66 | ||||||||

| M-20 | 1.64 | 4.40 | 1.72 | 5.80 | 6.70 | 8.50 | 8.00 | 1.52 | 1.23 | 3/4″ | 2.91 |

| M-22 | 1.75 | 7.50 | 7.00 | 1.65 | 1.36 | 7/8″ | 4.27 | ||||

| M-24 | 3.11 | 6.30 | 3.30 | 13.50 | 16.00 | 6.50 | 6.00 | 2.62 | 1.81 | 1″ | 6.13 |

| M-27 | 3.94 | 8.00 | 4.23 | 12.50 | 15.00 | 12.00 | 11.50 | 2.87 | 2.06 | 1.1/8″ | 7.69 |

| M-30 | 5.05 | 10.10 | 5.36 | 16.50 | 18.70 | 17.50 | 16.00 | 4.43 | 3.20 | 1.1/4″ | 9.90 |

| M-33 | 7.10 | 12.00 | 7.54 | 21.00 | 23.50 | 23.00 | 22.50 | 6.30 | 3.50 | ||

| M-36 | 8.73 | 14.60 | 9.20 | 25.50 | 29.20 | 26.50 | 26.00 | 6.73 | 5.25 | 1.1/2″ | 17.24 |

| M-39 | 12.60 | 16.70 | 13.30 | 28.30 | 34.50 | 7.17 | 5.61 | ||||

| M-42 | 17.50 | 20.10 | 18.30 | 11.10 | 8.00 | ||||||

| M-45 | 21.20 | 22.20 | 22.00 | 11.70 | 8.53 | ||||||

| M-48 | 28.40 | 26.00 | 29.40 | 12.30 | 9.00 | 2″ | 27.78 | ||||

| M-52 | 31.90 | 33.00 | 18.20 | ||||||||

| M-56 | 47.90 | 19.30 | |||||||||

| M-60 | 51.60 | 20.30 | |||||||||

| M-64 | 55.40 | 21.80 | |||||||||

| M-68 | 57.40 | ||||||||||

| M-72 | 63.40 | 24.00 | |||||||||

Chemical Composition of Grade 800/800H/800HT Incoloy Washers

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| Incoloy 800 | 0.10 max | 1.50 max | 1.00 max | 0.015max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Incoloy 800H | 0.05 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Incoloy 800HT | 0.06 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

Mechanical Properties of Incoloy 800/800H/800HT Washers

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Incoloy 800 / 800H / 800HT | 7.94 g/cm3 | 1385 °C (2525 °F) | Psi – 75,000 , MPa – 520 | Psi – 30,000 , MPa – 205 | 30 % |

Other Types of Incoloy 800/800H/800HT Washers

Incoloy 800 Washer

Incoloy 800HT Dome Washer

Incoloy 800H Hex Washers

ASTM B408 Incoloy 800 Tab Washer

800HT Incoloy Conical Washers

Incoloy Alloy 800H Lock Washer

Incoloy 1.4876 Cup Washers

Incoloy 800 Washers Stockist

Incoloy UNS N08800 Belleville Washers Supplier

ASME SB408 Alloy 800H Wave Washer

800HT Incoloy Bevel Washers

Alloy 800H Sealing Washer

ASME SB408 Incoloy 800 Hexagon Washer

Incoloy Alloy 800 Machine Washer

800HT Incoloy Dock Washers Exporter

Incoloy N08810 Split Lock Washer

Inconel OR XH32T Fender Washers

Inconel GOST ЭИ670 Punched Washer

Inconel EN X8NiCrAlTi32-21 Hexagonal Washer

Inconel DIN 1.4959 Spring Washers

Incoloy 800 ASTM B166 Fender Washers

Incoloy 800H OR XH32T Punched Washer

Incoloy 800HT Wedge Lock Washers

Incoloy 800 Countersunk Washers

Inconel JIS NCF 800H Flat Washers

ASTM B166 Industrial Washers Supplier in India

Incoloy 800HT Dome Tooth Washers

1.4958 Incoloy Washer Specification

Alloy 800 Tooth Washer

800HT Incoloy C Washer

800H Incoloy Finishing Washers

Incoloy Alloy 800 Hillside Washers

Grade 800 Incoloy Spherical Washers Manufacturer

Incoloy 800HT Washers Distributor

Incoloy N08811 Taper Washers

Incoloy 800HT Industrial Washer Price

ASTM B408 Incoloy 800H Serrated Washer

Incoloy UNS N08811 Split Washer

Incoloy DIN 1.4859 Spring Washer

800 Incoloy Split Ring Washers

Incoloy Alloy 800H Star Lock Washer

Incoloy 800HT Tooth Lock Washer

Incoloy 800 Hexagonal Washer Dealer

Incoloy 1.4876 Slotted Washers

Incoloy 800HT Hillside Washers Stockholder

Incoloy 800 Bearing Lock Washers

Incoloy 800H Spherical Washers in Mumbai

INOX 1.4959 Split /Lock Washer

Incoloy 800HT X8NiCrAlTi32-21 Lock Washer

Incoloy 800H BS NA 15(HT) Tab Washers

INOX 1.4959 Square Washers

ASME SB166 Incoloy 800 Machined Washers

Inconel N08811 Spherical Washer

Inconel Alloy 800 Tooth Lock Washer

Inconel Alloy 800HT Round Washer

Incoloy Alloy N08811 Washers

Incoloy 800/800H/800HT Washers Application Area

Our products range of Incoloy 800/800H/800HT Washers find application in various areas such as: Petro-Chemical Industries, Ship Building Industries, Heavy Engineering Industries, Fertilizer Plants, power Generation Units ( Nuclear, Hydro or Thermal), Civil Industries, Oil Expansion Projects, Off Shore & On Shore Oil Towers, Valves, Vessels, Pumps, Railways, Steel Plants, Civil Construction Industries, Home Fittings etc.