Table of Content

- What is SMO 254 Flanges

- SMO 254 Flanges Specification

- SMO 254 Flanges Equivalent Grade

- Types of SMO 254 Flanges

- SMO 254 Flanges Price List

- Chemical Composition of Grade SMO 254 Flanges

- Mechanical Properties of SMO 254 Flanges

- Other Types of SMO 254 Flanges

- SMO 254 Flanges Application Area

- Other Stock of SMO 254 Flanges

SMO 254 Flange, Best Deals on SMO UNS S31254 Flanges, SMO 254 Industrial Flanges, ASTM A182 SMO 254 Socket weld Flanges, Werkstoff Nr.1.4547 Slip On Flange, 254 SMO Forged Flanges, ANSI B16.5 SMO 254 Blind Flanges, 254 SMO Weld Neck Flange, SMO 254 SORF Flange Supplier in India.

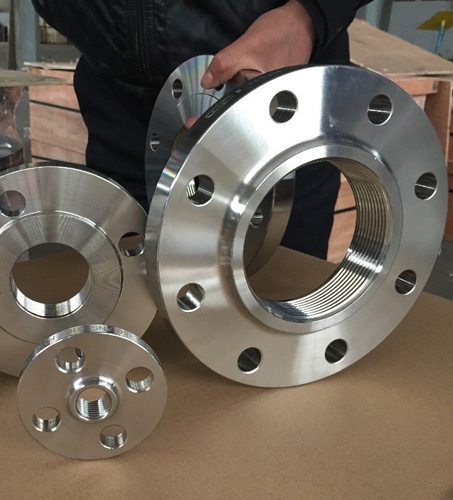

Kalpataru Piping Solutions is a well-known seller and stockist of SMO 254 Flanges, which are manufactured with precise diameter tolerance. Banking on the skills of our qualified team of professionals, we are involved in trading and Stockist of our 254 SMO Weldo Flanges, which are mainly used in Gas, Steam & Air Lines, Conveyor Industry, Oil & Gas Industry and Agriculture. Our valuable clients can avail this UNS S31254 Nipo Flanges from us in varied quantities at affordable prices, where we have firmly positioned ourselves as leading manufacturer and supplier of these products. We emerged as one of the fastest growing company to manufacture 254 SMO Threaded Flanges, where our growth and development tremendously paved way for us to establish our company. Our organization is highly known among the customers for distributing, supplying and trading a qualitative array of our WNR 1.4547 Paddle Blind Flanges, which is often used in HVAC for Hospitals, schools, university and industrial plants etc. Reckoned for accurate composition, this 254 SMO Ring Spacer Flanges is extensively used in air conditioning and refrigeration systems. We are engaged in providing a vast quality range of our SMO 254 Reducing Flanges to our clients, which are generally used for Water & Sewage Treatment. 254 SMO Hit Dip Galvanised Flanges is mainly used for grounding purposes, line tracing to locate underground utilities, drop wire of telephone cables, and inner conductor of coaxial cables, including thin hook-up cables.

Large Selection of SMO 254 Flanges, SMO 254 Long Weld Neck Flanges Dealer, ASME SA182 SMO 254 Orifice Flange, SMO DIN 1.4547 Lap Joint Flanges, SMO 254 Ring Type Joint Flanges, High Quality SMO 254 Threaded Flanges, Alloy 254 Square Flange, ASME / ANSI B16.5 SMO 254 Spectacle Blind Flange, 254 SMO WNRF Flange, SMO 254 Flanges Exporter.

SMO 254 Flanges Specification

SMO 254 Flanges Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS | SIS | AFNOR | EN |

| SMO 254 | 1.4547 | S31254 | 2378 | Z1 CNDU 20.18.06Az | X1CrNiMoCuN20-18-7 |

Types of SMO 254 Flanges

SMO 254 Weld Neck Flange

SMO 254 Blind Flange

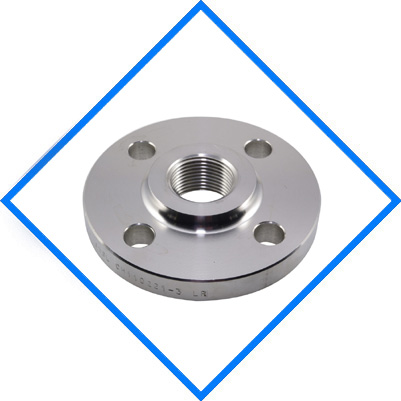

SMO 254 Threaded Flange

SMO 254 Orifice Flange

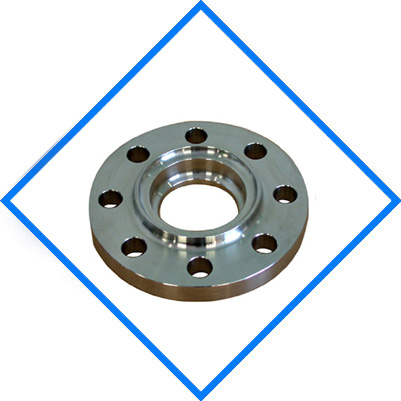

SMO 254 Slip on Flange

SMO 254 Long Weld Neck Flange

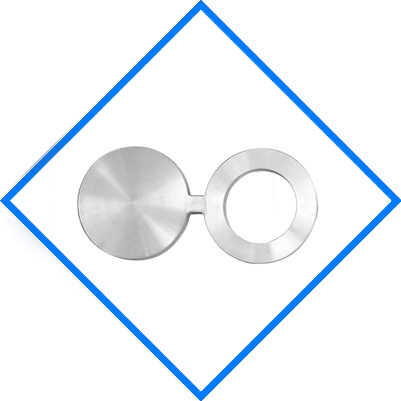

SMO 254 Spectacle Blind Flange

SMO 254 Socket Weld Flange

SMO 254 Flanges Price List

We offer wide range of industrial SMO 254 Flanges that in compliance with IS, BS and DIN standards at best market prices in India. To know more about the latest price of SMO 254 Flanges Please Call +91 22-66337137 or Send an Email to info@flangesbolts.com

Chemical Composition of Grade 254 SMO Flanges

| Grade | C | Mn | Si | S | N | Ni | Cr | Fe | Mo | P |

| SMO 254 | 0.02 max | 1.0 max | 0.8 max | 0.01 max | 0.18 - 0.22 | 17.5 - 18.5 | 19.5 - 20.5 | Remainder | 6.0 - 6.5 | 0.03 max |

Mechanical Properties of SMO 254 Flanges

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| SMO 254 | 8.0 g/cm3 | 1320-1390 ℃ | 650 | 300 | 35 % |

Other Types of SMO 254 Flanges

SMO 254 Flange

SMO 254 Threaded Flanges

SMO 254 Socket weld Flanges

ANSI B16.5 SMO 254 Slip on Flanges

Stainless Steel SMO 254 Weld Neck Flanges

ASTM A182 254 SMO Lap Joint Flanges

SMO 1.4547 Blind Flanges

ASME B16.5 SMO 254 Flanges Stockist

SMO UNS S31254 Pipe Flanges Supplier

ASME SA182 SMO 254 Plate Flanges

SMO 254 Spectacle Blind Flange

Stainless Steel SMO 254 Spacer

ASME SA182 SMO 254 Nippolet Flange

254 SMO Hydraulic SAE Flanges

SMO 254 Flexible Hose Flange Exporter

254 SMO Tongue & Groove Flange

SMO 254 Flange Specification

Stainless Steel SMO 254 Orifice Flanges

SMO 254 Forged Flanges

SMO 254 Stainless Steel SORF Flange

254 SMO Ring Type Joint Flange

Grade 254 SMO WNRF Flange Manufacturer

SMO 254 Flanges Distributor

SMO S31254 Puddle Flange

254 SMO Industrial Flange Price

ASTM A182 SMO 254 Long Weld Neck Flange

SMO UNS S31254 Square Flanges

SMO DIN 1.4547 Loose Flanges

Alloy 254 Weldo Flangs

SMO 254 Reducing Flanges

254 SMO Screwed Flanges

SMO 254 RTJ Flanges Dealer

Alloy 254 BLRF Flanges

SMO S31254 Flanges

SMO 254 Flanges Application Area

Our products range of SMO 254 Flanges find application in various areas such as: Petro-Chemical Industries, Ship Building Industries, Heavy Engineering Industries, Fertilizer Plants, power Generation Units ( Nuclear, Hydro or Thermal), Civil Industries, Oil Expansion Projects, Off Shore & On Shore Oil Towers, Valves, Vessels, Pumps, Railways, Steel Plants, Civil Construction Industries, Home Fittings etc.