Carbon Steel Weld Neck Flange, ASME B16.5 Raised Face Weld Neck Flange, Best Deals on Raised Face Weld Neck Flanges, ASME / ANSI B16.5 Weld Neck Flanges, Nickel Alloy Weld Neck Flanges, Class 300 Weld Neck Flanges, ANSI B16.5 Weld Neck Flanges, BS1560 Weld Neck Flanges, Stainless Steel WNRF Flange Supplier in India.

Kalpatru is a popular stockist of Weld Neck Flanges, which offers higher creep and stress rupture properties. Since iron oxide has lower density, Stainless Steel Weld Neck Flanges expands and tends to flake and fall away. In comparison, Carbon Steel Weld Neck Flanges contain sufficient chromium to undergo passivation, forming an inert film of chromium oxide on the surface. The layer prevents further corrosion by blocking oxygen diffusion to the surface of Alloy Steel Weld Neck Flanges and stops corrosion from spreading into the bulk of the metal. The resistance to corrosion and staining, low maintenance, and familiar lustre make Super Duplex Steel Weld Neck Flanges an ideal material for many applications. Nickel Alloy Weld Neck Flanges has slightly improved corrosion resistance over sort chrome steel in powerfully oxidizing environments. Inconel Weld Neck Flanges is additionally advantageous for top temperature service thanks to its sensible mechanical properties. Monel Weld Neck Flanges is also an atomic niobium)/tantalum stabilized primary solution chromium-nickel steel. Hastelloy Weld Neck Flanges is developed to provide associate alloy with improved intergranular-corrosion resistance. Copper Nickel Weld Neck Flanges includes a rather improved corrosion resistance over completely different alloys of steel in powerfully oxidizing environments as a results of the addition of metal (niobium) and number. Titanium Weld Neck Flanges includes a slightly improved corrosion resistance over different alloys of chrome steel in powerfully oxidizing environments as a result of the addition of niobium (niobium) and atomic number.

Large Selection of Inconel Weld Neck Flanges, Class 1500 Weld Neck Flanges, Monel Weld Neck Flanges, Hastelloy Weld Neck Flange Dealer, Alloy Steel WNRF Flanges, ANSI B16.5 WNRF Flange, ANSI B16.5 150 LBS Weld Neck Flange, SS Weld Neck Flanges, High Quality Duplex Steel Welding Neck Flanges, ANSI/ASME B16.5 Class 600 Welding Neck Flange Exporter.

ASME B16.5 Weld Neck Flanges Specification

| ASME B16.5 ANSI B16.5 Class 150 Weld Neck Flanges Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| ANSI B16.5 Class 150 Weld Neck Flanges Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ASME Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ASME B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| ANSI B16.5 Class 150 Weld Neck Flanges Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| ANSI B16.5 Class 150 Weld Neck Flanges Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Most common types of ANSI B16.48 Class 150 Weld Neck Flanges | Forged / Threaded / Screwed / Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production technique |

|

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, , Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Origin | Indian / West Europe / Japan / USA / Korean |

| Manufacturer of | ASME DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc.

|

| ANSI B16.48 Class 150 Weld Neck Flanges Uses & application |

|

| Stainless Steel ANSI B16.5 Class 150 Weld Neck Flanges | ASTM/ASME A/SA182 F304, F304L, F316, F316L, ASTM/ASME A/SA351 CF8, CF3, CF8M, CF3M, DIN 1.4301, DIN 1.4306, DIN 1.4401, DIN 1.4404, DIN 1.4308, DIN 1.4408, DIN 1.4306, DIN 1.4409 |

| Carbon Steel ANSI B16.5 Class 150 Weld Neck Flanges | ASTM/ASME A/SA105 A/SA105N & A/SA216-WCB, DIN 1.0402, DIN 1.0460, DIN 1.0619, Die Steel, ASTM A105 / ASME SA105, A105N, ASTM A350 LF2 / ASME SA350, High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80) |

| Alloy Steel ANSI B16.5 Class 150 Weld Neck Flanges | ASTM A182 / ASME SA182 F5, F9, F11, F12, F22, F91 |

| Titanium ANSI B16.5 Class 150 Weld Neck Flanges | ASTM B381 / ASME SB381, Titanium Gr. 1, Titanium Gr. 2, Titanium Gr. 4, Titanium Gr. 5, Titanium Gr. 7 ASTM R50250/GR.1 | R50400/GR.2 | R50550/GR.3 | R50700/GR.4 | GR.6 |R52400/GR.7 | R53400/GR.12 | R56320/GR.9 |R56400/GR.5 |

| Copper Nickel ANSI B16.5 Class 150 Weld Neck Flanges | ASTM / ASME SB 61 / 62 / 151 / 152, Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640 |

| Inconel ANSI B16.5 Class 150 Weld Neck Flanges | ASTM B564 / ASME SB564, Inconel 600, 601, 625, 718, 783, 690, x750 ANSI B16.5 Class 150 Blind Flanges |

| Hastelloy ANSI B16.5 Class 150 Weld Neck Flanges | ASTM B564 / ASME SB564, Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X Flanges |

| Monel ANSI B16.5 Class 150 Weld Neck Flanges | ASTM B564 / ASME SB564, Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500) |

| Alloy 20 ANSI B16.5 Class 150 Weld Neck Flanges | ASTM B462 / ASME SB462, Carpenter® 20 Alloy, Alloy 20Cb-3 |

| Nickel ANSI B16.5 Class 150 Weld Neck Flanges | ASTM B564 / ASME SB564, Nickel 200, Nickel 201, Nickel 205, Nickel 205LC |

| Duplex ANSI B16.5 Class 150 Weld Neck Flanges | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Super Duplex ANSI B16.5 Class 150 Weld Neck Flanges | S32750 / S32760 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Incoloy ANSI B16.5 Class 150 Weld Neck Flanges | ASTM B564 / ASME SB564, Incoloy 800, 800H, 800HT (UNS N08800), 825 (UNS N08825), 925 Flanges |

Weld Neck Flanges Material & Grades

| Stainless Steel Weld Neck Flanges | |

| ASTM A182 F 304, 304L, 304H, 309, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H, 446, 904L | |

| Carbon Steel Weld Neck Flanges | |

| ASTM A105, ASTM A694 Gr. F42, 46, 52, 56, 60, 65, 70 | |

| Alloy Steel Weld Neck Flanges | |

| ASTM A182, F1, F5, F9, F11, F22, F91 | |

| Duplex Steel Weld Neck Flanges | |

| ASTM A182, F44, F45, F51, F53, F55, F60, F61 | |

| Super Duplex Weld Neck Flanges | |

| ASTM A182, F44, F45, F51, F53, F55, F60, F61 | |

| High Nickel Alloy Weld Neck Flanges | |

| ASTM B564, B160, B472, B162, Nickel 200 (UNS No. No2200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade 2 & 5), Cupro-Nickel 70/30, Cupro-Nickel 90/10. | |

| Low Temperature Carbon Steel Weld Neck Flanges | |

| ASTM A350, LF2, LF3 | |

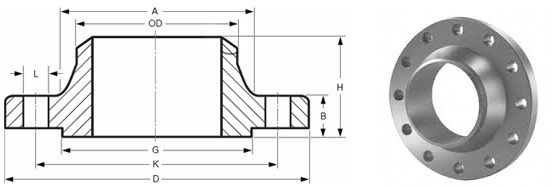

Dimensions of Weld Neck Flanges

ø |

D |

b |

g |

m |

a |

J* |

h |

k |

Holes |

l |

Kg. |

1/2" |

88,9 |

11,1 |

34,9 |

30,2 |

21,3 |

15,7 |

47,6 |

60,3 |

4 |

15,9 |

0,500 |

3/4" |

98,4 |

12,7 |

42,9 |

38,1 |

26,7 |

20,8 |

52,4 |

69,8 |

4 |

15,9 |

0,700 |

1" |

107,9 |

14,3 |

50,8 |

49,2 |

33,5 |

26,7 |

55,6 |

79,4 |

4 |

15,9 |

1,100 |

1 1/4" |

117,5 |

15,9 |

63,5 |

58,8 |

42,2 |

35,1 |

57,1 |

88,9 |

4 |

15,9 |

1,500 |

1 1/2" |

127,0 |

17,5 |

73,0 |

65,1 |

48,3 |

40,9 |

61,9 |

98,4 |

4 |

15,9 |

1,800 |

2" |

152,4 |

19,0 |

92,1 |

77,8 |

60,3 |

52,6 |

63,5 |

120,6 |

4 |

19,0 |

2,700 |

2 1/2" |

177,8 |

22,2 |

104,8 |

90,5 |

73,1 |

62,7 |

69,8 |

139,7 |

4 |

19,0 |

4,400 |

3" |

190,5 |

23,8 |

127,0 |

107,9 |

88,9 |

78,0 |

69,8 |

152,4 |

4 |

19,0 |

5,200 |

3 1/2" |

215,9 |

23,8 |

139,7 |

122,2 |

101,6 |

90,2 |

71,4 |

177,8 |

8 |

19,0 |

6,400 |

4" |

228,6 |

23,8 |

157,2 |

134,9 |

114,3 |

102,4 |

76,2 |

190,5 |

8 |

19,0 |

7,500 |

5" |

254,0 |

23,8 |

185,7 |

163,5 |

141,2 |

128,3 |

88,9 |

215,9 |

8 |

22,2 |

9,200 |

6" |

279,4 |

25,4 |

215,9 |

192,1 |

168,4 |

154,2 |

88,9 |

241,3 |

8 |

22,2 |

11,000 |

8" |

342,9 |

28,6 |

269,9 |

246,1 |

219,1 |

202,7 |

101,6 |

298,4 |

8 |

22,2 |

18,300 |

10" |

406,4 |

30,2 |

323,8 |

304,8 |

273,0 |

254,5 |

101,6 |

361,9 |

12 |

25,4 |

25,000 |

12" |

482,6 |

31,7 |

381,0 |

365,1 |

323,8 |

304,8 |

114,3 |

431,8 |

12 |

25,4 |

39,000 |

14" |

533,4 |

34,9 |

412,7 |

400,0 |

355,6 |

336,5 |

127,0 |

476,2 |

12 |

28,6 |

51,000 |

16" |

596,9 |

36,5 |

469,9 |

457,2 |

406,4 |

387,3 |

127,0 |

539,7 |

16 |

28,6 |

60,000 |

18" |

635,0 |

39,7 |

533,4 |

504,8 |

457,2 |

438,1 |

139,7 |

577,8 |

16 |

31,7 |

71,000 |

20" |

698,5 |

42,9 |

584,2 |

558,8 |

508,0 |

488,9 |

144,5 |

635,0 |

20 |

31,7 |

88,000 |

22" |

749,3 |

46,0 |

641,2 |

609,6 |

558,8 |

539,7 |

149,2 |

692,1 |

20 |

34,9 |

102,000 |

24" |

812,8 |

47,6 |

692,1 |

663,6 |

609,6 |

590,5 |

152,4 |

749,3 |

20 |

34,9 |

119,000 |

* |

The data "J" corresponds to the STD schedule |

||||||||||

ANS I/ ASME / ASA B16.5 300lb/sq.in. Flange WN-RF |

|||||||||||

ø |

D |

b |

g |

m |

a |

J* |

h |

k |

Holes |

l |

Kg. |

1/2" |

95,2 |

14,3 |

34,9 |

38,1 |

21,3 |

15,7 |

52,4 |

66,7 |

4 |

15,9 |

0,900 |

3/4" |

117,5 |

15,9 |

42,9 |

47,6 |

26,7 |

20,8 |

57,1 |

82,5 |

4 |

19,0 |

1,500 |

1" |

123,8 |

17,5 |

50,8 |

54,0 |

33,5 |

26,7 |

61,9 |

88,9 |

4 |

19,0 |

1,900 |

1 1/4" |

133,3 |

19,0 |

63,5 |

63,5 |

42,2 |

35,1 |

65,1 |

98,4 |

4 |

19,0 |

2,600 |

1 1/2" |

155,6 |

20,6 |

73,0 |

69,8 |

48,3 |

40,9 |

68,3 |

114,3 |

4 |

22,2 |

3,300 |

2" |

165,1 |

22,2 |

92,1 |

84,1 |

60,3 |

52,6 |

69,8 |

127,0 |

8 |

19,0 |

3,600 |

2 1/2" |

190,5 |

25,4 |

104,8 |

100,0 |

73,1 |

62,7 |

76,2 |

149,2 |

8 |

22,2 |

5,400 |

3" |

209,5 |

28,6 |

127,0 |

117,5 |

88,9 |

78,0 |

79,4 |

168,3 |

8 |

22,2 |

7,400 |

3 1/2" |

228,6 |

30,2 |

139,7 |

133,3 |

101,6 |

90,2 |

81,0 |

184,1 |

8 |

22,2 |

8,900 |

4" |

254,0 |

31,7 |

157,2 |

146,0 |

114,3 |

102,4 |

85,7 |

200,0 |

8 |

22,2 |

11,900 |

5" |

279,4 |

34,9 |

185,7 |

177,8 |

141,2 |

128,3 |

98,4 |

234,9 |

8 |

22,2 |

16,000 |

6" |

317,5 |

36,5 |

215,9 |

206,4 |

168,4 |

154,2 |

98,4 |

269,9 |

12 |

22,2 |

20,200 |

8" |

381,0 |

41,3 |

269,9 |

260,3 |

219,1 |

202,7 |

111,1 |

330,2 |

12 |

25,4 |

31,000 |

10" |

444,5 |

47,6 |

323,4 |

320,7 |

273,0 |

254,5 |

117,5 |

387,3 |

16 |

28,6 |

44,300 |

12" |

520,7 |

50,8 |

381,0 |

374,6 |

323,8 |

304,8 |

130,2 |

450,8 |

16 |

31,7 |

64,000 |

14" |

584,2 |

54,0 |

412,7 |

425,4 |

355,6 |

336,5 |

142,9 |

514,3 |

20 |

31,7 |

88,000 |

16" |

647,7 |

57,1 |

469,9 |

482,6 |

406,4 |

387,3 |

146,0 |

571,5 |

20 |

34,9 |

113,000 |

18" |

711,2 |

60,3 |

533,4 |

533,4 |

457,2 |

438,1 |

158,7 |

628,6 |

24 |

34,9 |

134,000 |

20" |

774,7 |

63,5 |

584,2 |

587,4 |

508,0 |

488,9 |

161,9 |

685,8 |

24 |

34,9 |

171,000 |

22" |

838,2 |

66,7 |

641,2 |

641,2 |

558,8 |

539,7 |

165,1 |

742,9 |

24 |

41,3 |

195,000 |

24" |

914,4 |

69,8 |

692,1 |

701,7 |

609,6 |

590,5 |

168,3 |

812,8 |

24 |

41,3 |

238,000 |

* |

The data "J" corresponds to the STD schedule |

||||||||||

ANS I /ASME / ASA B16.5 600lb/sq.in. Flanges WN-RF |

||||||||||

ø |

D |

b |

g |

m |

J |

h |

k |

Holes |

l |

Kg. |

1/2" |

95,2 |

14,3 |

34,9 |

38,1 |

22,3 |

22,2 |

66,7 |

4 |

15,9 |

0,800 |

3/4" |

117,5 |

15,9 |

42,9 |

47,6 |

27,7 |

25,4 |

82,5 |

4 |

19,0 |

1,400 |

1" |

123,8 |

17,5 |

50,8 |

54,0 |

34,5 |

27,0 |

88,9 |

4 |

19,0 |

1,600 |

1 1/4" |

133,3 |

20,6 |

63,5 |

63,5 |

43,2 |

28,6 |

98,4 |

4 |

19,0 |

2,100 |

1 1/2" |

155,6 |

22,2 |

73,0 |

69,8 |

49,5 |

31,7 |

114,3 |

4 |

22,2 |

3,100 |

2" |

165,1 |

25,4 |

92,1 |

84,1 |

62,0 |

36,5 |

127,0 |

8 |

19,0 |

3,700 |

2 1/2" |

190,5 |

28,6 |

104,8 |

100,0 |

74,7 |

41,3 |

149,2 |

8 |

22,2 |

5,400 |

3" |

209,5 |

31,7 |

127,0 |

117,5 |

90,7 |

46,0 |

168,3 |

8 |

22,2 |

7,300 |

3 1/2" |

228,6 |

34,9 |

139,7 |

133,3 |

103,4 |

49,2 |

184,1 |

8 |

25,4 |

8,900 |

4" |

273,0 |

38,1 |

157,2 |

152,4 |

116,1 |

54,0 |

215,9 |

8 |

25,4 |

11,800 |

5" |

330,2 |

44,4 |

185,7 |

188,9 |

143,8 |

60,3 |

266,7 |

8 |

28,6 |

24,500 |

6" |

355,6 |

47,6 |

215,9 |

222,2 |

170,7 |

66,7 |

292,1 |

12 |

28,6 |

29,500 |

8" |

419,1 |

55,6 |

269,9 |

273,0 |

221,5 |

76,2 |

349,2 |

12 |

31,7 |

43,000 |

10" |

508,0 |

63,5 |

323,8 |

342,8 |

276,3 |

85,7 |

431,8 |

16 |

34,9 |

70,000 |

12" |

558,8 |

66,7 |

381,0 |

400,0 |

327,1 |

92,1 |

488,9 |

20 |

34,9 |

86,000 |

14" |

603,2 |

69,8 |

412,7 |

431,8 |

359,1 |

93,7 |

527,0 |

20 |

38,1 |

100,000 |

16" |

685,8 |

76,2 |

469,9 |

495,3 |

410,5 |

106,4 |

603,2 |

20 |

41,3 |

142,000 |

18" |

742,9 |

82,5 |

533,4 |

546,1 |

461,8 |

117,5 |

654,0 |

20 |

44,4 |

175,000 |

20" |

812,8 |

88,9 |

584,2 |

609,6 |

513,1 |

127,0 |

723,9 |

24 |

44,4 |

232,000 |

22" |

869,9 |

95,2 |

641,2 |

666,7 |

564,4 |

133,3 |

777,9 |

24 |

47,6 |

292,000 |

24" |

939,8 |

101,6 |

692,1 |

717,5 |

615,9 |

139,7 |

838,2 |

24 |

50,8 |

330,000 |

Dimensional Tolerance of ASME B16.5 Weld Neck Flange

| Outside Diameter ≤ 24 = 1.6 mm | > 24 = ± 3.2 mm |

Inside Diameter not applicable |

| Diameter of Contact Face 1.6 mm Raised Face = ± 0.8 mm 6.35 mm Raised Face, Tongue & Groove / Male-Female = ± 0.4 mm |

Outside Diameter of Hub ≤ 12 = + 2.4 mm / - 1.6 mm | ≥ 14 = ± 3.2 mm |

| Diameter of Counterbore not applicable |

Drilling Bolt Circle = 1.6 mm | Bolt Hole Spacing = ± 0.8 mm Eccentricity of Bolt Circle with Respect to Facing ≤ 2½ = 0.8 mm max. | ≥ 3 = 1.6 mm max. |

| Thickness ≤ 18 = + 3.2 mm / - 0 | ≥ 20 = + 4.8 mm / - 0 |

Length thru Hub ≤ 18 = + 3.2 mm / - 0.8 mm | ≥ 20 = + 4.8 mm / - 1.6 mm |

ASME B16.5 Weld Neck Flanges Price List

We offer wide range of industrial Weld Neck Flanges that in compliance with IS, BS and DIN standards at best market prices in India. To know more about the latest price of Stainless Steel Weld Neck Flanges Please Call +91 22-66337137 or Send an Email to info@flangesbolts.com

Other Types of Weld Neck Flanges

Stainless Steel Weld Neck Flanges

ASTM A403 SS Weld Neck Flanges

Raised Face Weld Neck Flanges

ASME B16.5 Weld Neck Flanges Specification

ASME B16.5 Class 150 Weld Neck Flanges

Duplex Steel 2205 Weld Neck Flanges Exporter

ASME B16.5 WNRF Flanges Stockist

ANSI/ ASME B 16.5 Weld Neck Flanges Stockist

ANSI B16.5 Weld Neck Flanges Supplier

ASME/ANSI B16.5 Welding Neck Flange

Carbon Steel Welding Neck Flanges

ANSI B16.5 Weld Neck Flange

ASTM A182 F316 WN Flange

Weld Neck Flanges ansi b16.5 12 Inch Class 150

ASME B16.5 Welding Neck Flange SCH80

WNRF Class 150 Flanges DN65

A105N WN Flange Class 600

A182 F304L Weld Neck Flange CL150

AWWA C207 Class d educing Flange

MSS SP-44 groove weld neck flange

Super Duplex 2507 Weld Neck Flanges

ANSI B16.5 Weld Neck Flanges Distributor

Monel Weld Neck Flange

ASME B16.5 Weld Neck Flanges Price

ANSI B16.5 Weld Neck Raised Face Flanges

PN16/3 Welding Neck Flange Price

Alloy Steel Weld Neck Flanges

WNRF Flange Manufacturer

Nickel Alloy Welding Neck Flanges

ASME B16.5 Inconel Weld Neck Flanges

ANSI/ASME B16.5 Hastelloy Welding Neck Flanges

Copper Nickel Weld Neck Flanges Dealer

Weld Neck raised face flange

Weld Neck Flange b16.47

A182 F304 Weld Neck Flange

Weld Neck Flange class 300

Weld Neck Flange Din 2527

Weld Neck Flange Rtj 1500

Weld Neck Flange Jis B2220

Kf Weld Neck Flange

Weld Neck Flange Class 900

Titanium Alloy Welding Neck Flanges

Weld Neck Flanges Application Area

Our products range of Weld Neck Flanges find application in various areas such as: Petro-Chemical Industries, Ship Building Industries, Heavy Engineering Industries, Fertilizer Plants, power Generation Units ( Nuclear, Hydro or Thermal), Civil Industries, Oil Expansion Projects, Off Shore & On Shore Oil Towers, Valves, Vessels, Pumps, Railways, Steel Plants, Civil Construction Industries, Home Fittings etc.