ASME B16.5 Raised Face Ring Spacer Flange, Nickel Alloy Ring Spacer Flanges, ASME / ANSI B16.5 Ring Spacer Flanges, Carbon Steel Ring Spacer Flange, ANSI B16.5 Ring Spacer Flanges, Best Deals on Raised Face Ring Spacer Flanges, Class 300 Ring Spacer Flanges, Stainless Steel Ring Spacer Flange Supplier in India.

Kalpataru Piping Solutions is an eminent manufacturer and exporter of Ring Spacer Flanges in the industry, which extends resistance to corrosion caused by reducing chemicals. Stainless Steel Ring Spacer Flanges does not perform well in more highly reducing environments such as those containing chlorides and sulphuric acid. Carbon Steel Ring Spacer Flanges can be easily welded and processed by standard shop fabrication practices. Alloy Steel Ring Spacer Flanges is the most common form of steel used around the world, largely due to its excellent corrosion resistance and value. Super Duplex Steel Ring Spacer Flanges performs well in fresh water service with low levels of chlorides (less than 100ppm). At higher chloride levels, Nickel Alloy Ring Spacer Flanges is susceptible to crevice corrosion and pitting. Working temperatures of 1652–2102°F (750–1150°C) for Inconel Ring Spacer Flanges are recommended for most hot working processes. Monel Ring Spacer Flanges contains between 16 and 24 percent chromium and up to 35 percent nickel—as well as small amounts of carbon and manganese. The slightly higher price point of Hastelloy Ring Spacer Flanges is well worth it in areas with high chloride exposure, especially the coast and heavily salted roadways. The best machining results for Titanium Ring Spacer Flanges are achieved with slower speeds, heavier feeds, excellent lubrication, sharp tooling and powerful rigid equipment. The durability makes Copper Nickel Ring Spacer Flanges easy to sanitize, and therefore ideal for kitchen and food applications.

ANSI B16.5 150 LBS Ring Spacer Flange, Large Selection of Inconel Ring Spacer Flanges, High Quality Duplex Steel Ring Spacer Flanges, ANSI B16.5 Ring Spacer Flange, Hastelloy Ring Spacer Flange Dealer, Class 1500 Ring Spacer Flanges, Monel Ring Spacer Flanges, Alloy Steel Ring Spacer Flanges, SS Ring Spacer Flanges, ANSI/ASME B16.5 Class 600 Ring Spacer Flange Exporter.

ASME B16.5 Ring Spacer Flanges Specification

Ring Spacer Flanges Material & Grades

| Stainless Steel Ring Spacer Flanges | |

| ASTM A182 F 304, 304L, 304H, 309, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H, 446, 904L | |

| Carbon Steel Ring Spacer Flanges | |

| ASTM A105, ASTM A694 Gr. F42, 46, 52, 56, 60, 65, 70 | |

| Alloy Steel Ring Spacer Flanges | |

| ASTM A182, F1, F5, F9, F11, F22, F91 | |

| Duplex Steel Ring Spacer Flanges | |

| ASTM A182, F44, F45, F51, F53, F55, F60, F61 | |

| Super Duplex Ring Spacer Flanges | |

| ASTM A182, F44, F45, F51, F53, F55, F60, F61 | |

| High Nickel Alloy Ring Spacer Flanges | |

| ASTM B564, B160, B472, B162, Nickel 200 (UNS No. No2200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade 2 & 5), Cupro-Nickel 70/30, Cupro-Nickel 90/10. | |

| Low Temperature Carbon Steel Ring Spacer Flanges | |

| ASTM A350, LF2, LF3 | |

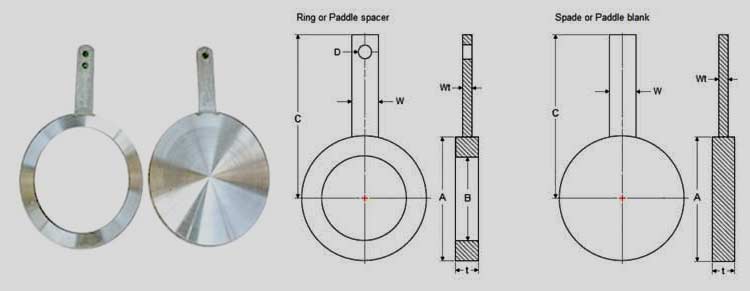

Dimensions of Ring Spacer Flanges

Pressure Class 150

| NPS | Outside Dia A |

Inside Dia B |

Center to End C |

Thick ness t |

Handle Width W |

| 1/2 | 45 | 16 | 126 | 3 | 32 |

| 3/4 | 54 | 21 | 131 | 3 | 32 |

| 1 | 64 | 27 | 136 | 3 | 32 |

| 1¼ | 73 | 42 | 145 | 6.4 | 32 |

| 1½ | 83 | 48 | 145 | 6.4 | 32 |

| 2 | 102 | 61 | 155 | 6.4 | 32 |

| 2½ | 107 | 73 | 170 | 6.4 | 32 |

| 3 | 133 | 89 | 170 | 6.4 | 32 |

| 3½ | 159 | 102 | 202 | 9.7 | 38 |

| 4 | 172 | 114 | 202 | 9.7 | 38 |

| 5 | 194 | 141 | 225 | 9.7 | 38 |

| 6 | 219 | 168 | 225 | 12.7 | 38 |

| 8 | 276 | 219 | 267 | 12.7 | 38 |

| 10 | 337 | 273 | 322 | 15.7 | 44 |

| 12 | 406 | 324 | 357 | 19.1 | 44 |

| 14 | 448 | 356 | 378 | 19.1 | 44 |

| 16 | 511 | 406 | 410 | 22.4 | 44 |

| 18 | 546 | 457 | 427 | 25.4 | 51 |

| 20 | 603 | 508 | 455 | 28.4 | 51 |

| 24 | 714 | 610 | 512 | 31.8 | 51 |

| NPS | Outside Dia A |

Inside Dia B |

Center to End C |

Thick ness t |

Handle Width W |

Pressure Class 300

| NPS | Outside Dia A |

Inside Dia B |

Center to End C |

Thick ness t |

Handle Width W |

| 1/2 | 51 | 16 | 129 | 6.4 | 32 |

| 3/4 | 64 | 21 | 136 | 6.4 | 32 |

| 1 | 70 | 27 | 139 | 6.4 | 32 |

| 1¼ | 79 | 42 | 150 | 6.4 | 32 |

| 1½ | 92 | 48 | 150 | 6.4 | 32 |

| 2 | 108 | 61 | 158 | 9.7 | 32 |

| 2½ | 127 | 73 | 177 | 9.7 | 32 |

| 3 | 146 | 89 | 177 | 9.7 | 32 |

| 3½ | 162 | 102 | 205 | 12.7 | 38 |

| 4 | 178 | 114 | 205 | 12.7 | 38 |

| 5 | 213 | 141 | 240 | 15.7 | 38 |

| 6 | 248 | 168 | 240 | 15.7 | 38 |

| 8 | 305 | 219 | 281 | 22.4 | 38 |

| 10 | 359 | 273 | 333 | 25.4 | 44 |

| 12 | 419 | 324 | 363 | 28.4 | 44 |

| 14 | 483 | 356 | 395 | 31.8 | 44 |

| 16 | 536 | 406 | 422 | 38.1 | 44 |

| 18 | 594 | 457 | 450 | 41.1 | 51 |

| 20 | 651 | 508 | 480 | 44.5 | 51 |

| 24 | 772 | 610 | 540 | 50.8 | 51 |

| NPS | Outside Dia A |

Inside Dia B |

Center to End C |

Thick ness t |

Handle Width W |

Pressure Class 600

| NPS | Outside Dia A |

Inside Dia B |

Center to End C |

Thick ness t |

Handle Width W |

| 1/2 | 51 | 16 | 129 | 6.4 | 32 |

| 3/4 | 64 | 21 | 136 | 6.4 | 32 |

| 1 | 70 | 27 | 139 | 6.4 | 32 |

| 1¼ | 79 | 37 | 150 | 9.7 | 32 |

| 1½ | 92 | 43 | 150 | 9.7 | 32 |

| 2 | 108 | 55 | 158 | 9.7 | 32 |

| 2½ | 127 | 67 | 177 | 12.7 | 32 |

| 3 | 146 | 83 | 177 | 12.7 | 32 |

| 3½ | 159 | 96 | 211 | 15.7 | 38 |

| 4 | 191 | 108 | 211 | 15.7 | 38 |

| 5 | 238 | 135 | 248 | 19.1 | 38 |

| 6 | 264 | 162 | 248 | 22.4 | 38 |

| 8 | 318 | 212 | 288 | 28.4 | 38 |

| 10 | 397 | 265 | 352 | 35.1 | 44 |

| 12 | 454 | 315 | 381 | 41.1 | 44 |

| 14 | 489 | 346 | 398 | 44.5 | 44 |

| 16 | 562 | 397 | 435 | 50.8 | 44 |

| 18 | 610 | 448 | 459 | 53.8 | 51 |

| 20 | 679 | 497 | 493 | 63.5 | 51 |

| 24 | 787 | 597 | 547 | 73.2 | 51 |

| NPS | Outside Dia A |

Inside Dia B |

Center to End C |

Thick ness t |

Handle Width W |

Pressure Class 900

| NPS | Outside Dia A |

Inside Dia B |

Center to End C |

Thick ness t |

Handle Width W |

| 1/2 | 60 | 16 | 134 | 6.4 | 32 |

| 3/4 | 67 | 21 | 137 | 6.4 | 32 |

| 1 | 76 | 27 | 142 | 6.4 | 32 |

| 1¼ | 86 | 37 | 151 | 9.7 | 32 |

| 1½ | 95 | 43 | 151 | 9.7 | 32 |

| 2 | 140 | 55 | 174 | 12.7 | 32 |

| 2½ | 162 | 67 | 186 | 12.7 | 32 |

| 3 | 165 | 83 | 186 | 15.7 | 32 |

| 4 | 203 | 108 | 217 | 19.1 | 38 |

| 5 | 244 | 135 | 259 | 22.4 | 38 |

| 6 | 286 | 162 | 259 | 25.4 | 38 |

| 8 | 356 | 212 | 307 | 35.1 | 38 |

| 10 | 432 | 265 | 370 | 41.1 | 44 |

| 12 | 495 | 315 | 401 | 47.8 | 44 |

| 14 | 518 | 346 | 412 | 53.8 | 44 |

| 16 | 572 | 397 | 440 | 60.5 | 44 |

| 18 | 635 | 448 | 471 | 66.5 | 51 |

| 20 | 696 | 497 | 501 | 73.2 | 51 |

| 24 | 835 | 597 | 571 | 88.9 | 51 |

| NPS | Outside Dia A |

Inside Dia B |

Center to End C |

Thick ness t |

Handle Width W |

Pressure Class 1500

| NPS | Outside Dia A |

Inside Dia B |

Center to End C |

Thick ness t |

Handle Width W |

| 1/2 | 61 | 16 | 135 | 6.4 | 32 |

| 3/4 | 67 | 21 | 137 | 9.7 | 32 |

| 1 | 76 | 27 | 142 | 9.7 | 32 |

| 1¼ | 86 | 35 | 151 | 9.7 | 32 |

| 1½ | 95 | 41 | 151 | 12.7 | 32 |

| 2 | 140 | 53 | 174 | 12.7 | 32 |

| 2½ | 162 | 63 | 190 | 15.7 | 32 |

| 3 | 172 | 78 | 190 | 19.1 | 32 |

| 4 | 206 | 102 | 219 | 22.4 | 38 |

| 5 | 251 | 128 | 256 | 28.4 | 38 |

| 6 | 279 | 154 | 256 | 35.1 | 38 |

| 8 | 349 | 203 | 303 | 41.1 | 38 |

| 10 | 432 | 255 | 370 | 50.8 | 44 |

| 12 | 518 | 303 | 412 | 60.5 | 44 |

| 14 | 575 | 333 | 442 | 66.5 | 44 |

| 16 | 638 | 381 | 472 | 76.2 | 44 |

| 18 | 702 | 429 | 504 | 85.9 | 51 |

| 20 | 752 | 478 | 530 | 95.3 | 51 |

| 24 | 899 | 575 | 603 | 111.3 | 51 |

| NPS | Outside Dia A |

Inside Dia B |

Center to End C |

Thick ness t |

Handle Width W |

Pressure Class 2500

| NPS | Outside Dia A |

Inside Dia B |

Center to End C |

Thick ness t |

Handle Width W |

| 1/2 | 67 | 16 | 137 | 9.7 | 32 |

| 3/4 | 73 | 21 | 140 | 9.7 | 32 |

| 1 | 83 | 27 | 145 | 9.7 | 32 |

| 1¼ | 102 | 35 | 161 | 12.7 | 32 |

| 1½ | 114 | 41 | 161 | 15.7 | 32 |

| 2 | 143 | 53 | 175 | 15.7 | 32 |

| 2½ | 165 | 63 | 201 | 19.1 | 32 |

| 3 | 194 | 78 | 201 | 22.4 | 32 |

| 4 | 232 | 102 | 232 | 28.4 | 38 |

| 5 | 276 | 128 | 273 | 35.1 | 38 |

| 6 | 314 | 154 | 273 | 41.1 | 38 |

| 8 | 384 | 198 | 321 | 53.8 | 38 |

| 10 | 473 | 248 | 390 | 66.5 | 44 |

| 12 | 546 | 289 | 427 | 79.2 | 44 |

| NPS | Outside Dia A |

Inside Dia B |

Center to End C |

Thick ness t |

Handle Width W |

ASME B16.5 Ring Spacer Flanges Price List

We offer wide range of industrial Ring Spacer Flanges that in compliance with IS, BS and DIN standards at best market prices in India. To know more about the latest price of Stainless Steel Ring Spacer Flanges Please Call +91 22-66337137 or Send an Email to info@flangesbolts.com

Other Types of Ring Spacer Flanges

Stainless Steel Ring Spacer Flanges

ASTM A403 SS Ring Spacer Flanges

Raised Face Ring Spacer Flanges

ASME B16.5 Ring Spacer Flanges Specification

ASME B16.5 Class 150 Ring Spacer Flanges

Duplex Steel 2205 Ring Spacer Flanges Exporter

ASME B16.5 Ring Spacer Flanges Stockist

ANSI/ ASME B 16.5 Ring Spacer Flanges Stockist

ANSI B16.5 Ring Spacer Flanges Supplier

ASME/ANSI B16.5 Ring Spacer Flange

Carbon Steel Ring Spacer Flanges

Super Duplex 2507 Ring Spacer Flanges

ANSI B16.5 Ring Spacer Flanges Distributor

Monel Ring Spacer Flange

ASME B16.5 Ring Spacer Flanges Price

ANSI B16.5 Ring Spacer Raised Face Flanges

PN16/3 Ring Spacer Flange Price

Alloy Steel Ring Spacer Flanges

Ring Spacer Flange Manufacturer

Nickel Alloy Ring Spacer Flanges

ASME B16.5 Inconel Ring Spacer Flanges

ANSI/ASME B16.5 Hastelloy Ring Spacer Flanges

Copper Nickel Ring Spacer Flanges Dealer

Titanium Alloy Ring Spacer Flanges

Ring Spacer Flanges Application Area

Our products range of Ring Spacer Flanges find application in various areas such as: Petro-Chemical Industries, Ship Building Industries, Heavy Engineering Industries, Fertilizer Plants, power Generation Units ( Nuclear, Hydro or Thermal), Civil Industries, Oil Expansion Projects, Off Shore & On Shore Oil Towers, Valves, Vessels, Pumps, Railways, Steel Plants, Civil Construction Industries, Home Fittings etc.