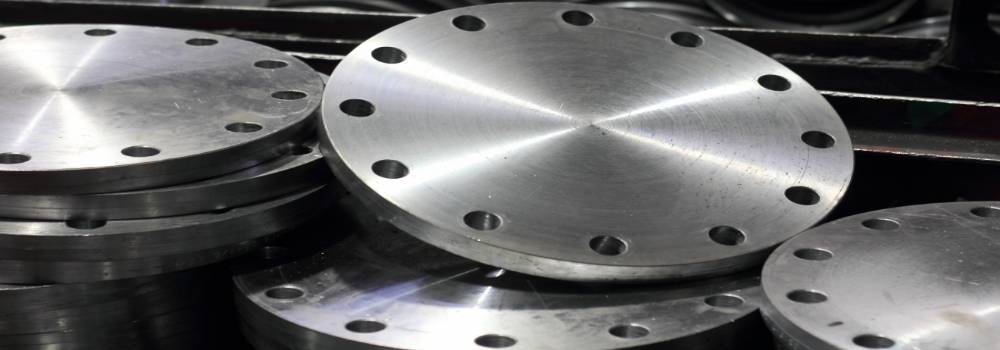

ANSI B16.5 Blind Flanges, Best Deals on Raised Face Blind Flanges, ASME / ANSI B16.5 Blind Flanges, Carbon Steel Blind Flange, Nickel Alloy Blind Flanges, Class 300 Blind Flanges, ASME B16.5 Raised Face Blind Flange, Stainless Steel BLRF Flange Supplier in India.

Kalpataru Piping Solutions is a popular trader of Blind Flanges, where the process of making it is highly specialised and complex. Stainless Steel Blind Flanges is alloyed with a variety of elements in total amounts between 1.0% and 50% by weight to improve its mechanical properties. These Carbon Steel Blind Flanges are trusted for their various salient features like corrosion resistance, durability and high tensile strength. Alloy Steel Blind Flanges is a metal alloy consisting mostly of iron, in addition to small amounts of carbon, depending on the grade and quality of the steel. Super Duplex Steel Blind Flanges are made by combining carbon steel with one or several alloying elements, such as manganese, silicon, nickel, titanium, copper, chromium and aluminium. Nickel Alloy Blind Flanges also contains niobium for stabilization against sensitization and resultant intergranular corrosion. Inconel Blind Flanges is tailor-made as per the customer’s specification and end application. Monel Blind Flanges is any type of steel to which one or more elements besides carbon have been intentionally added, to produce a desired physical property or characteristic. Common elements that are added to make Hastelloy Blind Flanges are molybdenum, manganese, nickel, silicon, boron, chromium, and vanadium. Titanium Blind Flanges is the top choice for any sort of situation where a combination of high strength, light weight, good corrosion resistance and high toughness are required. Copper Nickel Blind Flanges can be used in biomedical applications such as implantable components due to its biocompatibility, good fatigue strength and low modulus.

Alloy Steel BLRF Flanges, High Quality Duplex Steel BLRF Flanges, ANSI B16.5 BLRF Flange, ANSI B16.5 150 LBS Blind Flange, Large Selection of Inconel Blind Flanges, Hastelloy Blind Flange Dealer, Class 1500 Blind Flanges, Monel Blind Flanges, SS Blind Flanges, ANSI/ASME B16.5 Class 600 BLRF Flange Exporter.

ASME B16.5 Blind Flanges Specification

Blind Flanges Material & Grades

| Stainless Steel Blind Flanges | |

| ASTM A182 F 304, 304L, 304H, 309, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H, 446, 904L | |

| Carbon Steel Blind Flanges | |

| ASTM A105, ASTM A694 Gr. F42, 46, 52, 56, 60, 65, 70 | |

| Alloy Steel Blind Flanges | |

| ASTM A182, F1, F5, F9, F11, F22, F91 | |

| Duplex Steel Blind Flanges | |

| ASTM A182, F44, F45, F51, F53, F55, F60, F61 | |

| Super Duplex Blind Flanges | |

| ASTM A182, F44, F45, F51, F53, F55, F60, F61 | |

| High Nickel Alloy Blind Flanges | |

| ASTM B564, B160, B472, B162, Nickel 200 (UNS No. No2200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade 2 & 5), Cupro-Nickel 70/30, Cupro-Nickel 90/10. | |

| Low Temperature Carbon Steel Blind Flanges | |

| ASTM A350, LF2, LF3 | |

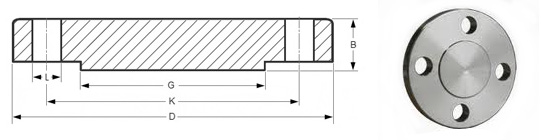

Dimensions of Blind Flanges

|

ANSI/ASME/ASA B16.5 150lb/sq.in. Flange BLIND-RF

|

|||||||

|

ø

|

D

|

b

|

g

|

k

|

Holes

|

l

|

Kg.

|

|

1/2"

|

88,9

|

11,1

|

34,9

|

60,3

|

4

|

15,9

|

0,400

|

|

3/4"

|

98,4

|

12,7

|

42,9

|

69,8

|

4

|

15,9

|

0,700

|

|

1"

|

107,9

|

14,3

|

50,8

|

79,4

|

4

|

15,9

|

0,900

|

|

1 1/4"

|

117,5

|

15,9

|

63,5

|

88,9

|

4

|

15,9

|

1,300

|

|

1 1/2"

|

127,0

|

17,5

|

73,0

|

98,4

|

4

|

15,9

|

1,600

|

|

2"

|

152,4

|

19,0

|

92,1

|

120,6

|

4

|

19,0

|

2,600

|

|

2 1/2"

|

177,8

|

22,2

|

104,8

|

139,4

|

4

|

19,0

|

4,100

|

|

3"

|

190,5

|

23,8

|

127,0

|

152,4

|

4

|

19,0

|

5,000

|

|

3 1/2"

|

215,9

|

23,8

|

139,7

|

177,8

|

8

|

19,0

|

6,400

|

|

4"

|

228,6

|

23,8

|

157,2

|

190,5

|

8

|

19,0

|

7,100

|

|

5"

|

254,0

|

23,8

|

185,7

|

215,9

|

8

|

22,2

|

9,000

|

|

6"

|

279,4

|

25,4

|

215,9

|

241,3

|

8

|

22,2

|

11,800

|

|

8"

|

342,9

|

28,6

|

269,9

|

298,4

|

8

|

22,2

|

21,000

|

|

10"

|

406,4

|

30,2

|

323,4

|

361,9

|

12

|

25,4

|

30,000

|

|

12"

|

482,6

|

31,7

|

381,0

|

431,8

|

12

|

25,4

|

45,000

|

|

14"

|

533,4

|

34,9

|

412,7

|

476,2

|

12

|

28,6

|

59,000

|

|

16"

|

596,9

|

36,5

|

469,9

|

539,9

|

16

|

28,6

|

79,000

|

|

18"

|

635,0

|

39,7

|

533,4

|

577,8

|

16

|

31,7

|

97,000

|

|

20"

|

698,5

|

42,9

|

584,2

|

635,0

|

20

|

31,7

|

124,000

|

|

22"

|

749,3

|

46,0

|

641,2

|

692,1

|

20

|

34,9

|

151,000

|

|

24"

|

812,8

|

47,6

|

692,1

|

749,3

|

20

|

34,9

|

188,000

|

|

ANSI/ASME/ASA B16.5 300lb/sq.in. Flange BLIND-RF

|

|||||||

|

ø

|

D

|

b

|

g

|

k

|

Holes

|

l

|

Kg.

|

|

1/2"

|

95,2

|

14,3

|

34,9

|

66,7

|

4

|

15,9

|

0,700

|

|

3/4"

|

117,5

|

15,9

|

42,9

|

82,5

|

4

|

19,0

|

1,200

|

|

1"

|

123,8

|

17,5

|

50,8

|

88,9

|

4

|

19,0

|

1,500

|

|

1 1/4"

|

133,3

|

19,0

|

63,5

|

98,4

|

4

|

19,0

|

2,000

|

|

1 1/2"

|

155,6

|

20,6

|

73,0

|

114,3

|

4

|

22,2

|

2,900

|

|

2"

|

165,1

|

22,2

|

92,1

|

127,0

|

8

|

19,0

|

3,400

|

|

2 1/2"

|

190,5

|

25,4

|

104,8

|

149,2

|

8

|

22,2

|

5,100

|

|

3"

|

209,5

|

28,6

|

127,0

|

168,3

|

8

|

22,2

|

7,000

|

|

3 1/2"

|

228,6

|

30,2

|

139,7

|

184,1

|

8

|

22,2

|

8,900

|

|

4"

|

254,0

|

31,7

|

157,2

|

200,0

|

8

|

22,2

|

11,800

|

|

5"

|

279,4

|

34,9

|

185,7

|

234,9

|

8

|

22,2

|

15,500

|

|

6"

|

317,5

|

36,5

|

215,9

|

269,9

|

12

|

22,2

|

21,300

|

|

8"

|

381,0

|

41,3

|

269,9

|

330,2

|

12

|

25,4

|

35,200

|

|

10"

|

444,5

|

47,6

|

323,8

|

387,3

|

16

|

28,6

|

57,000

|

|

12"

|

520,7

|

50,8

|

381,0

|

450,8

|

16

|

31,7

|

82,000

|

|

14"

|

584,2

|

54,0

|

412,7

|

514,3

|

20

|

31,7

|

106,000

|

|

16"

|

647,7

|

57,1

|

469,9

|

571,5

|

20

|

34,9

|

140,000

|

|

18"

|

711,2

|

60,3

|

533,4

|

628,6

|

24

|

34,9

|

178,000

|

|

20"

|

774,7

|

63,5

|

584,2

|

685,8

|

24

|

34,9

|

223,000

|

|

22"

|

838,2

|

66,7

|

641,2

|

742,9

|

24

|

41,3

|

270,000

|

|

24"

|

914,4

|

69,8

|

692,1

|

812,8

|

24

|

41,3

|

345,000

|

|

ANSI/ASME/ASA B16.5 600lb/sq.in. Flange BLIND-RF

|

|||||||

|

ø

|

D

|

b

|

g

|

k

|

Holes

|

l

|

Kg.

|

|

1/2"

|

95,2

|

14,3

|

34,9

|

66,7

|

4

|

15,9

|

0,700

|

|

3/4"

|

117,5

|

15,9

|

42,9

|

82,5

|

4

|

19,0

|

1,200

|

|

1"

|

123,8

|

17,5

|

50,8

|

88,9

|

4

|

19,0

|

1,500

|

|

1 1/4"

|

133,3

|

20,6

|

63,5

|

98,4

|

4

|

19,0

|

2,000

|

|

1 1/2"

|

155,6

|

22,2

|

73,0

|

114,3

|

4

|

22,2

|

3,200

|

|

2"

|

165,1

|

25,4

|

92,1

|

127,0

|

8

|

19,0

|

4,300

|

|

2 1/2"

|

190,5

|

28,6

|

104,8

|

149,2

|

8

|

22,2

|

6,000

|

|

3"

|

209,5

|

31,7

|

127,0

|

168,3

|

8

|

22,2

|

8,000

|

|

3 1/2"

|

228,6

|

34,9

|

139,7

|

184,1

|

8

|

25,4

|

10,500

|

|

4"

|

273,0

|

38,1

|

157,2

|

215,9

|

8

|

25,4

|

18,000

|

|

5"

|

330,2

|

44,4

|

185,7

|

266,7

|

8

|

28,6

|

28,500

|

|

6"

|

355,6

|

47,6

|

215,9

|

292,1

|

12

|

28,6

|

35,500

|

|

8"

|

419,1

|

55,6

|

269,9

|

349,2

|

12

|

31,7

|

58,000

|

|

10"

|

508,0

|

63,5

|

323,8

|

431,8

|

16

|

34,9

|

98,000

|

|

12"

|

558,8

|

66,7

|

381,0

|

488,9

|

20

|

34,9

|

125,000

|

|

14"

|

603,2

|

69,8

|

412,7

|

527,0

|

20

|

38,1

|

151,000

|

|

16"

|

685,8

|

76,2

|

469,9

|

603,2

|

20

|

41,3

|

215,000

|

|

18"

|

742,9

|

82,5

|

533,4

|

654,0

|

20

|

44,4

|

287,000

|

|

20"

|

812,8

|

88,9

|

584,2

|

723,9

|

24

|

44,4

|

366,000

|

|

22"

|

869,9

|

95,2

|

641,2

|

777,9

|

24

|

47,6

|

437,000

|

|

24"

|

939,8

|

101,6

|

692,1

|

838,2

|

24

|

50,8

|

532,000

|

Dimensional Tolerances of Blind Flange ASME B16.5

| Outside Diameter ≤ 24 = 1.6 mm | > 24 = ± 3.2 mm |

Inside Diameter not applicable |

| Diameter of Contact Face 1.6 mm Raised Face = ± 0.8 mm 6.35 mm Raised Face, Tongue & Groove / Male-Female = ± 0.4 mm |

Outside Diameter of Hub ≤ 12 = + 2.4 mm / - 1.6 mm | ≥ 14 = ± 3.2 mm |

| Diameter of Counterbore not applicable |

Drilling Bolt Circle = 1.6 mm | Bolt Hole Spacing = ± 0.8 mm Eccentricity of Bolt Circle with Respect to Facing ≤ 2½ = 0.8 mm max. | ≥ 3 = 1.6 mm max. |

| Thickness ≤ 18 = + 3.2 mm / - 0 | ≥ 20 = + 4.8 mm / - 0 |

Length thru Hub ≤ 18 = + 3.2 mm / - 0.8 mm | ≥ 20 = + 4.8 mm / - 1.6 mm |

ASME B16.5 Blind Flanges Price List

We offer wide range of industrial Blind Flangesthat in compliance with IS, BS and DIN standards at best market prices in India. To know more about the latest price of Stainless Steel Blind Flanges Please Call +91 22-66337137 or Send an Email to info@flangesbolts.com

Other Types of Blind Flanges

Stainless Steel Blind Flanges

ASTM A403 SS Blind Flanges

Raised Face Blind Flanges

ASME B16.5 Blind Flanges Specification

ASME B16.5 Class 150 Blind Flanges

Duplex Steel 2205 Blind Flanges Exporter

ASME B16.5 BLRF Flanges Stockist

ANSI/ ASME B 16.5 Blind Flanges Stockist

ANSI B16.5 Blind Flanges Supplier

ASME/ANSI B16.5 BLRF Flange

Carbon Steel BLRF Flanges

Super Duplex 2507 Blind Flanges

ANSI B16.5 Blind Flanges Distributor

Monel Blind Flange

ASME B16.5 Blind Flanges Price

ANSI B16.5 Blind Raised Face Flanges

PN16/3 BLRF Flange Price

Alloy Steel Blind Flanges

BLRF Flange Manufacturer

Nickel Alloy BLRF Flanges

ASME B16.5 Inconel Blind Flanges

ANSI/ASME B16.5 Hastelloy BLRF Flanges

Copper Nickel Blind Flanges Dealer

Titanium Alloy BLRF Flanges

Blind Flanges Application Area

Our products range of Blind Flanges find application in various areas such as: Petro-Chemical Industries, Ship Building Industries, Heavy Engineering Industries, Fertilizer Plants, power Generation Units ( Nuclear, Hydro or Thermal), Civil Industries, Oil Expansion Projects, Off Shore & On Shore Oil Towers, Valves, Vessels, Pumps, Railways, Steel Plants, Civil Construction Industries, Home Fittings etc.