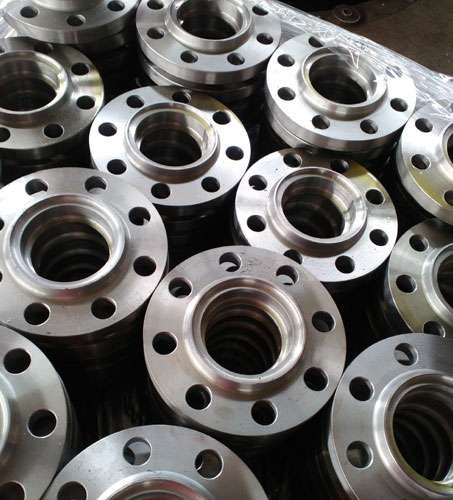

Korean Standard Flange, Flat Faced Korean Standard Flange, SS Korean Standard Flange, Best Deals on Korean Flanges, KS B 1503 5K-40K Flange, KS B1503 Weld Neck Flange, KS D 3578 Blind Flange, Stainless Steel Korean Flange, KS D 4308 Flange, Carbon Steel Korean Flange, Alloy Steel Korean Flange Supplier in India.

Kalpataru Piping Solutions is one of the best manufacturer of Korean Flanges, which requires low speeds and constant feeds to reduce its tendency to work harden. Stainless Steel Korean Flanges is a low carbon version that largely includes 18% to 20% chromium and 11% to 15% nickel. Carbon Steel Korean Flanges is molybdenum demeanour austenitic steel which is comparatively similar, but in the company of higher molybdenum substance. Alloy Steel Korean Flanges can be supplied in cut-to length sizes and as well fabricated or machined to meet up your customized piping requirements. Super Duplex Steel Korean Flanges has the same high strength and corrosion resistance but can produce stronger welds due to the low carbon content. Inconel Korean Flanges is tougher with a long stringy chip; however, using chip breakers is recommended. The material in Monel Korean Flanges should be heated to 1149-1260 Degree C (2100-2300 Degree F); however, it should not be heated below 927 Degree C (1700 Degree F). To optimize corrosion resistance, a post-work annealing is recommended here in Hastelloy Korean Flanges that are being offered at customized and standard sizes so as to one can choose accordingly. Nickel Alloy Korean Flanges is often used in Chemical and petrochemical process equipment, pulp and paper manufacturing and condensers in fossil and nuclear fueled power generation stations. For use in marine and automotive applications, our Titanium Korean Flanges are perfect steel available with varying tensions.

KS D 3578 Flange Dimensions, Korean Standard Raised Face Flange, ANSI B16.47 Korean Flange, ANSI CL 150-300 Korean Flange, Hastelloy Korean Flange, High Quality Duplex Steel Korean Flanges, Inconel Korean Flange Dealer, Large Selection of Monel Korean Flanges, Nickel Alloy 200 Korean Flange, Korean Blind Flanges, Korean Slip on Flanges, Korean Flange Exporter.

Korean Flanges Specification

Dimensions of Korean Standard Flange

| KS B 1503 5K Flange | KS D 4308 Flange | DIN 6 BAR Flange | ANSI CL 400-600 Flange |

| KS B 1503 10K Flange | KS D 3578 Flange | DIN 10 BAR Flange | ANSI CL 900 Flange |

| KS B 1503 16K Flange | KS B 2332 & 2333 Flange | DIN 16 BAR Flange | ANSI CL 1500-2500 Flange |

| KS B 1503 20K Flange | KS B 6216 Flange | DIN 25 BAR Flange | JIS – KS Material Specifications |

| KS B 1503 30K Flange | KS B 6216 Flange | DIN 40 BAR Flange | |

| KS B 1503 40K Flange | KS B 6216 Flange | ANSI CL 150-300 Flange |

Korean Flanges Material & Grades

| Stainless Steel Korean Flanges | |

| ASTM/ASME A/SA182 F304, F304L, F316, F316L, ASTM/ASME A/SA351 CF8, CF3, CF8M, CF3M, DIN 1.4301, DIN 1.4306, DIN 1.4401, DIN 1.4404, DIN 1.4308, DIN 1.4408, DIN 1.4306, DIN 1.4409 | |

| Carbon Steel Korean Flanges | |

| ASTM/ASME A/SA105 A/SA105N & A/SA216-WCB, DIN 1.0402, DIN 1.0460, DIN 1.0619, Die Steel, ASTM A105 / ASME SA105, A105N, ASTM A350 LF2 / ASME SA350, High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80) | |

| Alloy Steel Korean Flanges | |

| ASTM A182 / ASME SA182 F5, F9, F11, F12, F22, F91 | |

| Duplex Steel Korean Flanges | |

| S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 | |

| Super Duplex Korean Flanges | |

| S32750 / S32760 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 | |

| Titanium Korean Flanges | |

| ASTM B381 / ASME SB381, Titanium Gr. 1, Titanium Gr. 2, Titanium Gr. 4, Titanium Gr. 5, Titanium Gr. 7 ASTM R50250/GR.1 | R50400/GR.2 | R50550/GR.3 | R50700/GR.4 | GR.6 |R52400/GR.7 | R53400/GR.12 | R56320/GR.9 |R56400/GR.5 | |

| Copper Korean Flanges | |

| T1, T2, C10100, C10200, C10300, C10400, C10500, C10700, C10800, C10910,C10920, TP1, TP2, C10930, C11000, C11300, C11400, C11500, C11600, C12000,C12200, C12300, TU1, TU2, C12500, C14200, C14420, C14500, C14510, C14520, C14530, C17200, C19200, C21000, C23000, C26000, C27000, C27400, C28000, C33000, C33200, C37000, C44300, C44400, C44500, C60800, C63020, C68700, C70400, C70600, C70620, C71000, C71500, C71520, C71640, etc | |

| Copper Nickel Korean Flanges | |

| ASTM / ASME SB 61 / 62 / 151 / 152, Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640 | |

| Inconel Korean Flanges | |

| ASTM B564 / ASME SB564, Inconel 600, 601, 625, 718, 783, 690, x750 Korean | |

| Hastelloy Korean Flanges | |

| ASTM B564 / ASME SB564, Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X Flanges | |

| Monel Korean Flanges | |

| ASTM B564 / ASME SB564, Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500) | |

| Alloy 20 Korean Flanges | |

| ASTM B462 / ASME SB462, Carpenter® 20 Alloy, Alloy 20Cb-3 | |

| Aluminium Korean Flanges | |

| 5052 /6061/ 6063 / 2017 / 7075 / etc. | |

| Nickel Korean Flanges | |

| ASTM B564 / ASME SB564, Nickel 200, Nickel 201, Nickel 205, Nickel 205LC | |

| Incoloy Korean Flanges | |

| ASTM B564 / ASME SB564, Incoloy 800, 800H, 800HT (UNS N08800), 825 (UNS N08825), 925 Flanges | |

| 254 SMO Korean Flanges | |

| ASTM A182 / ASME SA182, SMO 254/6Mo, UNS S31254, DIN 1.4547 | |

| Nimonic Korean Flanges | |

| Nimonic 75, Nimonic 80A, Nimonic 90 | |

| Brass Korean Flanges | |

| 3602 / 2604 / H59 / H62 / etc | |

| Other Korean Flanges Material | |

| Tin bronze, Alumunum bronze, Lead bronze | |

Korean Flanges Price List

We offer wide range of industrial Korean Flanges that in compliance with IS, BS and DIN standards at best market prices in India. To know more about the latest price of Stainless Steel Korean Flanges Please Call +91 22-66337137 or Send an Email to info@flangesbolts.com

Weight Chart Of Korean Flange

| NPS (Inches) |

DN (mm) |

FLANGE OD A MM |

FLANGE THICKNESS D MM |

SLIP ON FLANGE WEIGHT (KGS) | WELD NECK FLANGE WEIGHT (KGS) | BLIND FLANGE WEIGHT (KGS) |

| 1/ 2 | 15 | 88.9 | 11.2 | 0.4 | 0.5 | 0.4 |

| 3/ 4 | 20 | 98.6 | 12.7 | 0.6 | 0.7 | 0.6 |

| 1 | 25 | 108 | 14.2 | 0.8 | 1 | 0.9 |

| 1 1/ 4 | 32 | 117.3 | 15.7 | 1 | 1.3 | 1.2 |

| 1 1/ 2 | 40 | 127 | 17.5 | 1.3 | 1.7 | 1.5 |

| 2 | 50 | 152.4 | 19.1 | 2.1 | 2.6 | 2.4 |

| 2 1/ 2 | 65 | 177.8 | 22.4 | 3.3 | 4.1 | 3.9 |

| 3 | 80 | 190.5 | 23.9 | 3.9 | 4.9 | 4.9 |

| 3 1/ 2 | 90 | 215.9 | 23.9 | 4.8 | 6.1 | 6.2 |

| 4 | 100 | 228.6 | 23.9 | 5.3 | 6.8 | 7.0 |

| 5 | 125 | 254 | 23.9 | 6.1 | 8.6 | 8.6 |

| 6 | 150 | 279.4 | 25.4 | 7.5 | 10.6 | 11.3 |

| 8 | 200 | 342.9 | 28.4 | 12.1 | 17.6 | 19.6 |

| 10 | 250 | 406.4 | 30.2 | 16.5 | 24 | 28.6 |

| 12 | 300 | 482.6 | 31.8 | 26.2 | 36.5 | 43.2 |

| 14 | 350 | 533.4 | 35.1 | 34.6 | 48.4 | 58.1 |

| 16 | 400 | 596.9 | 36.6 | 44.8 | 60.6 | 76.1 |

| 18 | 450 | 635 | 39.6 | 48.9 | 68.3 | 93.7 |

| 20 | 500 | 698.5 | 42.9 | 61.9 | 84.5 | 122.0 |

| 24 | 600 | 812.8 | 47.8 | 86.9 | 115 | 185.0 |

Other Types of Korean Flanges

Stainless Steel Korean Flanges

SS Korean Flanges

Korean Raised Face Flanges

ASME B16.5 Korean Flange

KS B 1503 5K-40K Flange

Duplex Steel Korean Flanges Exporter

DIN 6-40 BAR Korean Flange Stockist

Korean Flanges Stockist

Korean Flanges Supplier

Carbon Steel Korean Flange

Alloy Steel Korean Flange

Super Duplex Korean Flanges

Inconel Korean Flange

Nickel 200 Korean Flange

Hastelloy Korean Flange

KS B 1503 10K Flange

ANSI B16.5 Korean Flanges

KS 5KG Flange

Korean Orifice Flanges

ANSI CL 900 Flange

ANSI CL 400-600 Flange

KS B 1503 16K Flange

KS B 1503 20K Flange

Korean Socket weld Flanges

Korean Threaded Flanges

Korean Long weld Neck Flanges

KS D 4308 Flange

KS D 3578 Flange Dimensions

Flat Faced Korean Standard Flange

Korean Forged Flanges Distributor

Monel Korean Flange

Korean Reducing Flanges

Korean Slip-On Flanges

Korean Flange Price

KS 10KG Flange

Korean RTJ Flanges

KS 16KG Flange

Korean Square Flanges

Korean Flange Manufacturer

Korean Class 150 Flanges

Inconel Korean Pipe Flanges

Class 600 Korean Flanges

Copper Nickel Korean Flanges Dealer

Titanium Korean Flanges

Korean Forged Flanges

Korean Blind Flange

Korean Ring Type Joint Flanges

Korean Weld Neck Flange

DIN 25 BAR Flange

ANSI CL 1500-2500 Flange

DIN 40 BAR Flange

ANSI CL 150-300 Flange

DIN 6 BAR Flange

DIN 10 BAR Flange

KS B 2332 & 2333 Flange

KS B 6216 Flange

KS B 1503 30K Flange

KS B 1503 10K Flange

Korean Flanges Application Area

Our products range of Korean Flanges find application in various areas such as: Petro-Chemical Industries, Ship Building Industries, Heavy Engineering Industries, Fertilizer Plants, power Generation Units ( Nuclear, Hydro or Thermal), Civil Industries, Oil Expansion Projects, Off Shore & On Shore Oil Towers, Valves, Vessels, Pumps, Railways, Steel Plants, Civil Construction Industries, Home Fittings etc.