Best Deals on Raised Face Groove & Tongue Flanges, Nickel Alloy Groove & Tongue Flanges, Carbon Steel Groove & Tongue Flange, ASME B16.5 Raised Face Groove & Tongue Flange, ANSI B16.5 Groove & Tongue Flanges, ASME / ANSI B16.5 Groove & Tongue Flanges, Class 300 Groove & Tongue Flanges, Stainless Steel Tongue and Groove Flange Supplier in India.

Kalpataru Piping Solutions is an eminent manufacturer of Groove & Tongue Flanges in the industry, where post-weld annealing is not required. Stainless Steel Groove & Tongue Flanges absolutely was developed for increased creep resistance and for higher strength at temperatures higher than 1000°F (537°C). In most instances, the carbon content of Carbon Steel Groove & Tongue Flanges permits twin certification. Alloy Steel Groove & Tongue Flanges doesn't perform well in chloride solutions, even in tiny concentrations, or in sulphuric acid. Super Duplex Steel Groove & Tongue Flanges intermittent heating between 800ºF (427ºC) and 1650ºF (899ºC), or for attachment below conditions that stop a post-weld temper. Nickel Alloy Groove & Tongue Flanges can't be hardened by heat treatment, solely by cold operating. Monel Groove & Tongue Flanges may be simply welded and processed by commonplace search fabrication practices. Hastelloy Groove & Tongue Flanges are used because they are not sensitive to intergranular corrosion after heating within the carbide precipitation range of 425-850°C. A limitation with Inconel Groove & Tongue Flanges is that titanium does not transfer well across a high temperature arc, so is not recommended as a welding consumable. Titanium Groove & Tongue Flanges is the grade of choice for applications in the temperature range of up to about 900°C. Copper Nickel Groove & Tongue Flanges combines high strength, resistance to scaling and phase stability with resistance to subsequent aqueous corrosion.

SS Groove & Tongue Flanges, Hastelloy Groove & Tongue Flange Dealer, Large Selection of Inconel Groove & Tongue Flanges, Class 1500 Groove & Tongue Flanges, Monel Groove & Tongue Flanges, Alloy Steel Tongue and Groove Flanges, High Quality Duplex Steel Tongue and Groove Flanges, ANSI B16.5 Tongue and Groove Flange, ANSI B16.5 150 LBS Groove & Tongue Flange, ANSI/ASME B16.5 Class 600 Tongue and Groove Flange Exporter.

ASME B16.5 Groove & Tongue Flanges Specification

Groove & Tongue Flanges Material & Grades

| Stainless Steel Groove & Tongue Flanges | |

| ASTM A182 F 304, 304L, 304H, 309, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H, 446, 904L | |

| Carbon Steel Groove & Tongue Flanges | |

| ASTM A105, ASTM A694 Gr. F42, 46, 52, 56, 60, 65, 70 | |

| Alloy Steel Groove & Tongue Flanges | |

| ASTM A182, F1, F5, F9, F11, F22, F91 | |

| Duplex Steel Groove & Tongue Flanges | |

| ASTM A182, F44, F45, F51, F53, F55, F60, F61 | |

| Super Duplex Groove & Tongue Flanges | |

| ASTM A182, F44, F45, F51, F53, F55, F60, F61 | |

| High Nickel Alloy Groove & Tongue Flanges | |

| ASTM B564, B160, B472, B162, Nickel 200 (UNS No. No2200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade 2 & 5), Cupro-Nickel 70/30, Cupro-Nickel 90/10. | |

| Low Temperature Carbon Steel Groove & Tongue Flanges | |

| ASTM A350, LF2, LF3 | |

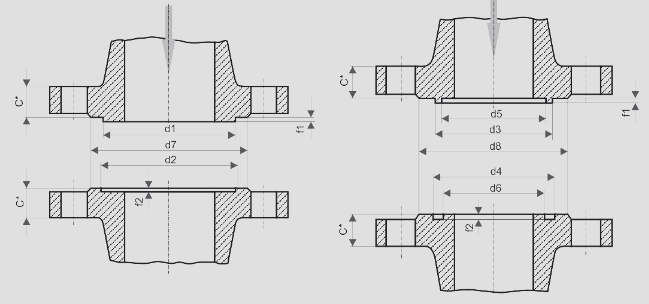

Dimensions of Groove & Tongue Flanges

ANSI B16.5 Class 300# Groove & Tongue Flanges Dimensions

Nominal |

Large Tongue |

Large Tongue |

Gasket |

Number |

Size of |

Bolt Torque |

Comp Force |

Max. Gasket |

Internal |

Min. Rec’d |

Min. Rec’d |

Max. Rec’d/Avail. |

Preferred |

Pipe Size |

Contact I.D. |

Contact O.D. |

Contact Area |

Of |

Bolts |

at 60ksi Stress |

Per Bolt @ 60ksi |

Stress Avail. |

Pressure |

Gasket Stress |

Torque/Bolt |

Gasket Stress |

Torque/Bolt |

(in) |

(in) |

(in) |

(sq.in.) |

Bolts |

(in) |

(ft.lbs.) |

(psi) |

(psi) |

(psig) |

(psi) |

(ft.lbs.) |

(psi) |

(ft.lbs.) |

0.5 |

1.00 |

1.38 |

0.71 |

4 |

0.50 |

60 |

7560 |

42594 |

<800 |

6200 |

12 |

10000 |

14 |

0.75 |

1.31 |

1.69 |

0.89 |

4 |

0.63 |

120 |

12120 |

54174 |

<800 |

6200 |

21 |

10000 |

22 |

1 |

1.50 |

2.00 |

1.37 |

4 |

0.63 |

120 |

12120 |

35290 |

<800 |

6400 |

28 |

10000 |

34 |

1.25 |

1.88 |

2.50 |

2.13 |

4 |

0.63 |

120 |

12120 |

22742 |

<800 |

6400 |

43 |

10000 |

53 |

1.5 |

2.12 |

2.88 |

2.98 |

4 |

0.75 |

200 |

18120 |

24298 |

<800 |

6400 |

64 |

10000 |

82 |

2 |

2.88 |

3.62 |

3.78 |

8 |

0.63 |

120 |

12120 |

25679 |

<800 |

6400 |

46 |

10000 |

47 |

2.5 |

3.38 |

4.12 |

4.36 |

8 |

0.75 |

200 |

18120 |

33273 |

<800 |

6400 |

60 |

10000 |

60 |

3 |

4.25 |

5.00 |

5.45 |

8 |

0.75 |

200 |

18120 |

26618 |

<800 |

6400 |

88 |

10000 |

75 |

3.5 |

4.75 |

5.50 |

6.03 |

8 |

0.75 |

200 |

18120 |

24021 |

<800 |

6400 |

99 |

10000 |

83 |

4 |

5.19 |

6.19 |

8.93 |

8 |

0.75 |

200 |

18120 |

16227 |

<800 |

6400 |

125 |

10000 |

123 |

5 |

6.31 |

7.31 |

10.69 |

8 |

0.75 |

200 |

18120 |

13558 |

<800 |

6400 |

156 |

10000 |

148 |

6 |

7.50 |

8.50 |

12.56 |

12 |

0.75 |

200 |

18120 |

17312 |

<800 |

6400 |

131 |

10000 |

116 |

8 |

9.38 |

10.62 |

19.47 |

12 |

0.88 |

320 |

25140 |

15496 |

<800 |

6400 |

205 |

10000 |

207 |

10 |

11.25 |

12.75 |

28.26 |

16 |

1.00 |

490 |

33060 |

18718 |

<800 |

6400 |

219 |

10000 |

262 |

12 |

13.50 |

15.00 |

33.56 |

16 |

1.13 |

710 |

43680 |

20826 |

<800 |

6400 |

319 |

15000 |

511 |

14 |

14.75 |

16.25 |

36.50 |

20 |

1.13 |

710 |

43680 |

23933 |

<800 |

6600 |

287 |

15000 |

445 |

16 |

16.75 |

18.50 |

48.42 |

20 |

1.25 |

1000 |

55740 |

23021 |

<800 |

6600 |

401 |

15000 |

652 |

18 |

19.25 |

21.00 |

55.29 |

24 |

1.25 |

1000 |

55740 |

24194 |

<800 |

6400 |

439 |

15000 |

620 |

20 |

21.00 |

23.00 |

69.08 |

24 |

1.25 |

1000 |

55740 |

19365 |

<800 |

6400 |

484 |

15000 |

775 |

24 |

25.25 |

27.25 |

82.43 |

24 |

1.50 |

1600 |

84300 |

24546 |

<800 |

6400 |

662 |

15000 |

978 |

ASME B16.5 Groove & Tongue Flanges Price List

We offer wide range of industrial Groove & Tongue Flanges that in compliance with IS, BS and DIN standards at best market prices in India. To know more about the latest price of Stainless Steel Groove & Tongue Flanges Please Call +91 22-66337137 or Send an Email to info@flangesbolts.com

Other Types of Groove & Tongue Flanges

Stainless Steel Groove & Tongue Flanges

ASTM A403 SS Groove & Tongue Flanges

Raised Face Groove & Tongue Flanges

ASME B16.5 Groove & Tongue Flanges Specification

ASME B16.5 Class 150 Groove & Tongue Flanges

Duplex Steel 2205 Groove & Tongue Flanges Exporter

ASME B16.5 Tongue and Groove Flanges Stockist

ANSI/ ASME B 16.5 Groove & Tongue Flanges Stockist

ANSI B16.5 Groove & Tongue Flanges Supplier

ASME/ANSI B16.5 Tongue and Groove Flange

Carbon Steel Tongue and Groove Flanges

Super Duplex 2507 Groove & Tongue Flanges

ANSI B16.5 Groove & Tongue Flanges Distributor

Monel Groove & Tongue Flange

ASME B16.5 Groove & Tongue Flanges Price

ANSI B16.5 Groove & Tongue Raised Face Flanges

PN16/3 Tongue and Groove Flange Price

Alloy Steel Groove & Tongue Flanges

Tongue and Groove Flange Manufacturer

Nickel Alloy Tongue and Groove Flanges

ASME B16.5 Inconel Groove & Tongue Flanges

ANSI/ASME B16.5 Hastelloy Tongue and Groove Flanges

Copper Nickel Groove & Tongue Flanges Dealer

Titanium Alloy Tongue and Groove Flanges

Groove & Tongue Flanges Application Area

Our products range of Groove & Tongue Flanges find application in various areas such as: Petro-Chemical Industries, Ship Building Industries, Heavy Engineering Industries, Fertilizer Plants, power Generation Units ( Nuclear, Hydro or Thermal), Civil Industries, Oil Expansion Projects, Off Shore & On Shore Oil Towers, Valves, Vessels, Pumps, Railways, Steel Plants, Civil Construction Industries, Home Fittings etc.