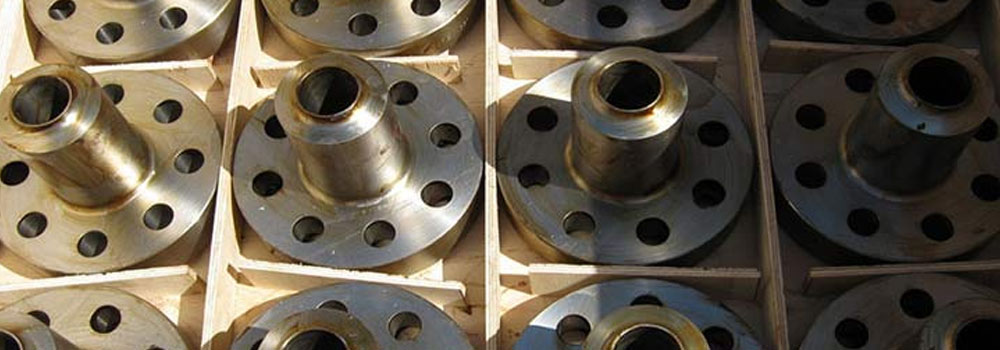

Carbon Steel Weldo Flange, ASME / ANSI B16.5 Weldo Flanges, ANSI B16.5 Weldo Flanges, ASME B16.5 Raised Face Weldo Flange, Best Deals on Raised Face Weldo Flanges, Nickel Alloy Weldo Flanges, Class 300 Weldo Flanges, Stainless Steel Weldo Flange Supplier in India.

Kalpatru is an eminent trader of Weldo Flanges in the industry, which has slightly improved corrosion resistance in strongly oxidizing environments. Stainless Steel Weldo Flanges is a molybdenum bearing, low carbon content grade austenitic steel that provides improved corrosion resistance. Carbon Steel Weldo Flanges is non-magnetic in the annealed condition but may become slightly magnetic as a result of welding. Alloy Steel Weldo Flanges has excellent corrosion resistance in a wide range of chemicals, especially in acidic chloride environments such as those encountered in pulp and paper mills. Super Duplex Steel Weldo Flanges offers higher creep and stress rupture properties and be considered for exposures where sensitization and intergranular corrosion are concerns. Nickel Alloy Weldo Flanges is a heat resistant, titanium stabilized, austenitic alloy that's commonly used for service in the 1000°-1600°F temperature range. Inconel Weldo Flanges use nickel to keep up associate degree primary solid solution composition at lower temperatures. Monel Weldo Flanges could be a cluster of primary solid solution stainless-steels with superior corrosion resistance to an untarnished steel. Hastelloy Weldo Flanges is appropriate for fastening as a result of its carbon content to avoid inorganic compound precipitation in fastening applications. Titanium Weldo Flanges includes in equipment within the chemical, food, paper, mining, and pharmaceutical and fossil oil industries. Copper Nickel Weldo Flanges conjointly provide higher creep, stress-to-rupture and durability at elevated temperatures. Alloy 20 Flanges have glorious corrosion resistance and strength properties, and that they square measure likeminded for unreal or shaped applications.

Large Selection of Inconel Weldo Flanges, Monel Weldo Flanges, SS Weldo Flanges, High Quality Duplex Steel Weldo Flanges, ANSI B16.5 Weldo Flange, ANSI B16.5 150 LBS Weldo Flange, Hastelloy Weldo Flange Dealer, Alloy Steel Weldo Flanges, Class 1500 Weldo Flanges, ANSI/ASME B16.5 Class 600 Weldo Flange Exporter.

ASME B16.5 Weldo Flanges Specification

| Weldo Flange Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 Weldo Flange |

|---|---|

| JIS ANSI B16.5 Weldoflange | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K Weldo Flange |

| UNI ASME B16.47 Weldoflange | 6Bar 10Bar 16Bar 25Bar 40Bar Weldo Flange |

| ASME B16.5 Weldo Flange Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

| Standard MSS-SP-44 Weldoflange | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Weldo Flange, ASME Weldo Flange, BS Weldo Flange, DIN Weldo Flange, EN Weldo Flange, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Weldo Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS Weldo Flange |

| EN ANSI B16.5 Weldoflange dimensions | 6Bar 10Bar 16Bar 25Bar 40Bar Weldo Flange |

| Coating For SS Weldoflange | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized Weldo Flange |

| Most common types of Weldo Flange | Forged / Threaded / Screwed / Plate |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production technique |

|

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Origin | Indian / West Europe / Japan / USA / Korean |

| Weldo Flange Uses & application |

|

| Manufacturer of ANSI B16.5 Class 150 Weldoflange | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc.

|

| Export to ANSI 150 Weldo Flange Dimensions | Ireland, Singapore, Indonesia, Ukraine, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Iran, India, Egypt, Oman, Dubai, Peru, etc |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Weldo Flanges Material & Grades

| Stainless Steel Weldo Flanges | |

| ASTM A182 F 304, 304L, 304H, 309, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H, 446, 904L | |

| Carbon Steel Weldo Flanges | |

| ASTM A105, ASTM A694 Gr. F42, 46, 52, 56, 60, 65, 70 | |

| Alloy Steel Weldo Flanges | |

| ASTM A182, F1, F5, F9, F11, F22, F91 | |

| Duplex Steel Weldo Flanges | |

| ASTM A182, F44, F45, F51, F53, F55, F60, F61 | |

| Super Duplex Weldo Flanges | |

| ASTM A182, F44, F45, F51, F53, F55, F60, F61 | |

| High Nickel Alloy Weldo Flanges | |

| ASTM B564, B160, B472, B162, Nickel 200 (UNS No. No2200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade 2 & 5), Cupro-Nickel 70/30, Cupro-Nickel 90/10. | |

| Low Temperature Carbon Steel Weldo Flanges | |

| ASTM A350, LF2, LF3 | |

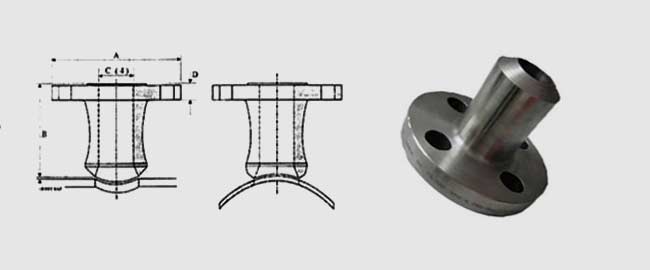

Dimensions of Weldo Flanges

| NPS | A | D | B | C |

|---|---|---|---|---|

| 1/2 | 3/4 19.05 |

5/8 15.88 |

1.3/8 34.93 |

15/16 23.81 |

| 3/4 | 7/8 22.23 |

13/16 20.64 |

1.5/8 41.28 |

1.3/16 30.16 |

| 1 | 1.1/16 26.99 |

1.1/32 26.19 |

2 50.80 |

1.7/16 36.51 |

| 1.1/4 | 1.1/4 31.75 |

1.3/8 34.93 |

2.3/8 60.3 |

1.3/4 44.45 |

| 1.1/2 | 1.5/16 33.34 |

1.5/8 41.28 |

2.7/8 73 |

2 50.80 |

| 2 | 1.1/2 38.10 |

2.1/16 52.39 |

3.1/2 88.90 |

2.9/16 65.09 |

| 2.1/2 | 1.5/8 41.28 |

2.7/16 61.91 |

4.1/16 103.19 |

3 76.20 |

| 3 | 1.3/4 44.45 |

3.1/16 77.79 |

4.13/16 122.24 |

3.11/16 93.66 |

| 3.1/2 | 2 50.80 |

3.9/16 90.49 |

5.3/8 136.53 |

3.7/8 98.43 |

| 4 | 2 50.80 |

4 101.60 |

6 152.40 |

4.3/4 120.65 |

| 5 | 2.1/4 57.15 |

5.1/16 128.59 |

7.1/8 180.98 |

5.9/16 141.29 |

| 6 | 2.3/8 60.3 |

6.1/16 153.99 |

8.1/2 215.90 |

6.11/16 169.86 |

| 8 | 2.3/4 69.85 |

7.15/16 201.61 |

10.3/8 263.53 |

8.11/16 220.66 |

| 10 | 3.1/16 77.79 |

10 254.00 |

12.9/16 319.09 |

10.13/16 274.64 |

| 12 | 3.3/8 85.73 |

12 304.80 |

14.7/8 377.83 |

12.13/16 325.44 |

| 14 | 3.1/2 88.90 |

13.1/4 336.55 |

16.1/8 409.58 |

14.1/16 357.19 |

| 16 | 3.11/16 93.66 |

15.1/4 387.35 |

18.1/4 463.55 |

16.1/16 407.99 |

| 18 | 4.1/16 103.19 |

17.1/4 438.15 |

20.3/4 527.05 |

18.5/8 473.08 |

| 20 | 4.5/8 117.48 |

19.1/4 488.95 |

23.1/16 585.79 |

20.1/16 509.59 |

| 24 | 5.3/8 136.53 |

23.1/4 590.55 |

27.7/8 708.03 |

25.1/8 638.18 |

| NPS | A | D | B | C |

ASME B16.5 Weldo Flanges Price List

We offer wide range of industrial Weldo Flanges that in compliance with IS, BS and DIN standards at best market prices in India. To know more about the latest price of Stainless Steel Weldo Flanges Please Call +91 22-66337137 or Send an Email to info@flangesbolts.com

Other Types of Weldo Flanges

Stainless Steel Weldo Flanges

ASTM A403 SS Weldo Flanges

Raised Face Weldo Flanges

ASME B16.5 Weldo Flanges Specification

ASME B16.5 Class 150 Weldo Flanges

Duplex Steel 2205 Weldo Flanges Exporter

ASME B16.5 Weldo Flanges Stockist

ANSI/ ASME B 16.5 Weldo Flanges Stockist

ANSI B16.5 Weldo Flanges Supplier

ASME/ANSI B16.5 Weldo Flange

Carbon Steel Weldo Flanges

Hastelloy Weldo Flange

DIN-2527 Weldoflange

Monel Weldoflange

SS Weldoflange

ANSI B16.5 Class 150 Weldoflange

Super Duplex 2507 Weldo Flanges

ANSI B16.5 Weldo Flanges Distributor

Monel Weldo Flange

ASME B16.5 Weldo Flanges Price

ANSI B16.5 Weldo Raised Face Flanges

PN16/3 Weldo Flange Price

Alloy Steel Weldo Flanges

Weldo Flange Manufacturer

Nickel Alloy Weldo Flanges

ASME B16.5 Inconel Weldo Flanges

ANSI/ASME B16.5 Hastelloy Weldo Flanges

Copper Nickel Weldo Flanges Dealer

Class 150 LBS Weldo Flange

Nickel Alloy Weldoflange

Inconel Weldoflange

BS-4504 Weldoflange

Standard MSS-SP-44 Weldoflange

Titanium Alloy Weldo Flanges

Weldo Flanges Application Area

Our products range of Weldo Flanges find application in various areas such as: Petro-Chemical Industries, Ship Building Industries, Heavy Engineering Industries, Fertilizer Plants, power Generation Units ( Nuclear, Hydro or Thermal), Civil Industries, Oil Expansion Projects, Off Shore & On Shore Oil Towers, Valves, Vessels, Pumps, Railways, Steel Plants, Civil Construction Industries, Home Fittings etc.