Table of Content

- What is Titanium Gr 5 Flanges

- Titanium Gr 5 Flanges Specification

- Titanium Gr 5 Flanges Equivalent Grade

- Types of Titanium Gr 5 Flanges

- Titanium Gr 5 Flanges Price List

- Chemical Composition of Grade 5 Titanium Flanges

- Mechanical Properties of Titanium Gr 5 Flanges

- Other Types of Titanium Gr 5 Flanges

- Titanium Gr 5 Flanges Application Area

- Other Stock of Titanium Flanges

ASTM B381 Titanium Gr 5 Socket weld Flanges, Titanium Gr 5 Weld Neck Flange, Titanium Alloy Gr 5 Forged Flanges, ANSI B16.5 Titanium Grade 5 Blind Flanges, Best Deals on Titanium UNS R56400 Flanges, Titanium Gr 5 Industrial Flanges, Werkstoff Nr. 3.7165 Slip On Flange, Titanium Gr 5 Flange, Titanium Gr 5 SORF Flange Supplier in India.

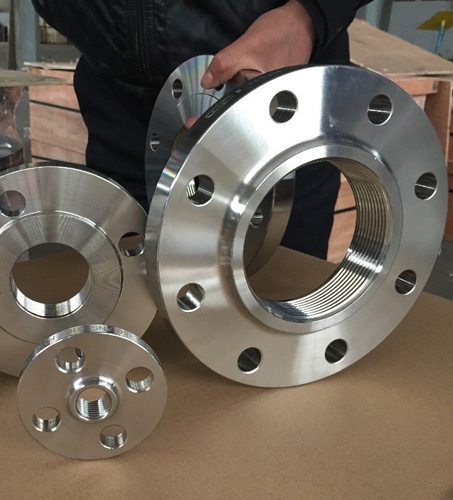

Kalpataru Piping Solutions is a well-known distributor and seller of Titanium Alloy Grade 5 Flanges, which are leading supplier in offering best quality at reliable price in market. Titanium Grade 5 Groove & Tongue Flanges that we manufacture are extensively used in Air conditioning systems in the Metal Plate, Metal Pipe, Metal Bar, Metal Flange, Construction Pipe, Stainless Steel Fastener and more. Ti Gr 5 Long Weld Neck Flanges are often used our stucco embossed aluminium sheet to cover walls, as sheet metal for trailers, locker rooms, public restrooms, airports, hospitals, and commercial kitchens. We are involved in dealing with these Grade 5 Titanium Ring Type Joint Flanges which are used for different applications such as Refrigerant Gas, Fridge Spare Parts, and so on. We grew to be one of the Pre - Eminent designer, supplier, installer, service provider and repairer of Gr 5 Ti-Alloy Weldo Flanges, which are often used in Washing Machine Spare Parts, Microwave Components and many more. We have manufactured these Titanium UNS R56400 Nipo Flanges using superior quality raw material and ultra - modern technology. Available at most competitive price, our range of Titanium 6Al-4V Threaded Flanges is stored properly in cylinders to avoid leakage. The range of Heat Exchangers Ti-6Al-4V Paddle Blind Flanges made with special alloys, are lighter but yet stronger than traditional soldered copper / brass radiators. Understanding the diversified needs of clients, we offer customized solutions to them for these Titanium WNR 3.7165 Ring Spacer Flanges and offer requisite recommendations to them.

Large Selection of Titanium Gr 5 Flanges, ASME / ANSI B16.5 Titanium Gr 5 Spectacle Blind Flange, Titanium Alloy DIN 3.7165 Lap Joint Flanges, Titanium Grade 5 WNRF Flange, High Quality Titanium Gr 5 Threaded Flanges, Titanium Grade 5 Square Flange, ASME SB381 Titanium Gr 5 Orifice Flange, Ti Alloy Grade 5 Long Weld Neck Flanges Dealer, Titanium Gr 5 Ring Type Joint Flanges, Titanium Gr 5 Flanges Exporter.

Titanium Gr 5 Flanges Specification

Titanium Gr 5 Flanges Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS |

| Gr 5 | 3.7165 | R56400 |

Types of Titanium Gr 5 Flanges

Titanium Gr 5 Weld Neck Flange

Titanium Gr 5 Blind Flange

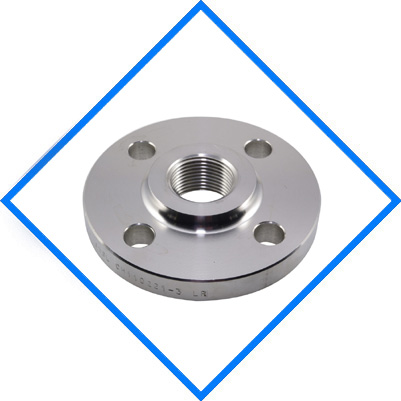

Titanium Gr 5 Threaded Flange

Titanium Gr 5 Orifice Flange

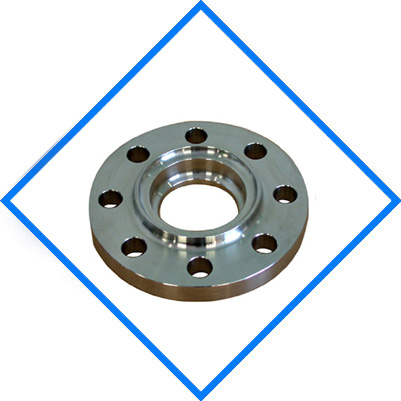

Titanium Gr 5 Slip on Flange

Titanium Gr 5 Long Weld Neck Flange

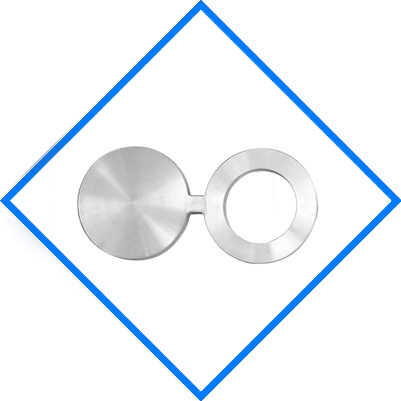

Titanium Gr 5 Spectacle Blind Flange

Titanium Gr 5 Socket Weld Flange

Titanium Gr 5 Flanges Price List

We offer wide range of industrial Titanium Gr 5 Flanges that in compliance with IS, BS and DIN standards at best market prices in India. To know more about the latest price of Titanium Grade 5 Flanges Please Call +91 22-66337137 or Send an Email to info@flangesbolts.com

Chemical Composition of Grade 5 Titanium Flanges

| Grade | N | C | H | Fe | O | Al | V |

| Ti Grade 5 | 0.05 max | 0.10 max | 0.01 max | 0.40 max | 0.20 max | 5.50-6.75 | 3.50-4.50 |

Mechanical Properties of Titanium Gr 5 Flanges

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Titanium Gr 5 | 4.43 g/cm3 | 1632 °C (2970 °F) | Psi – 138000 , MPa – 950 | Psi – 128000 , MPa – 880 | 14 % |

Other Types of Titanium Gr 5 Flanges

Titanium Gr 5 Flange

Titanium Grade 5 Threaded Flanges

Titanium Gr 5 Socket weld Flanges

ANSI B16.5 Titanium Gr 5 Slip on Flanges

Titanium Gr 5 Weld Neck Flanges

Ti Alloy Grade 5 ASTM B381 Lap Joint Flanges

Titanium 3.7165 Blind Flanges

ASME B16.5 Titanium Gr 5 Flanges Stockist

Titanium UNS R56400 Pipe Flanges Supplier

ASME SB381 Titanium Gr 5 Plate Flanges

Titanium Gr 5 Spectacle Blind Flange

Titanium Alloy Grade 5 Spacer

ASME SB381 Titanium Gr 5 Nippolet Flange

Titanium Gr 5 Hydraulic SAE Flanges

Titanium Gr 5 Flexible Hose Flange Exporter

Titanium Gr 5 Tongue & Groove Flange

Titanium Grade 5 Flange Specification

Titanium Gr 5 Orifice Flanges

Titanium Alloy Gr 5 Forged Flanges

Titanium Gr 5 SORF Flange

Ti Alloy Gr 5 Ring Type Joint Flange

Grade 5 Titanium WNRF Flange Manufacturer

Titanium Gr 5 Flanges Distributor

Ti Alloy R56400 Puddle Flange

Titanium Gr 5 Industrial Flange Price

ASTM B381 Titanium Gr 5 Long Weld Neck Flange

Titanium UNS R56400 Square Flanges

Titanium DIN 3.7165 Loose Flanges

Ti Alloy Gr 5 Weldo Flangs

Titanium Grade 5 Reducing Flanges

Titanium Alloy Gr 5 Screwed Flanges

Titanium Grade 5 RTJ Flanges Dealer

Titanium Gr 5 BLRF Flanges

Ti Alloy R56400 Flanges

Titanium Gr 5 Flanges Application Area

Our products range of Titanium Gr 5 Flanges find application in various areas such as: Petro-Chemical Industries, Ship Building Industries, Heavy Engineering Industries, Fertilizer Plants, power Generation Units ( Nuclear, Hydro or Thermal), Civil Industries, Oil Expansion Projects, Off Shore & On Shore Oil Towers, Valves, Vessels, Pumps, Railways, Steel Plants, Civil Construction Industries, Home Fittings etc.